- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

F2 F3 End mphero kwa machining othamanga kwambiri a aluminiyamu

High liwiro Machining a aluminiyamu

HJA600 End mphero Kwa High liwiro Machining a aluminiyamu

Oyenera High liwiro Machining a aluminiyamu ndi zitsulo zotayidwa aloyi

Oyenera kagawo ndi roughing ntchito

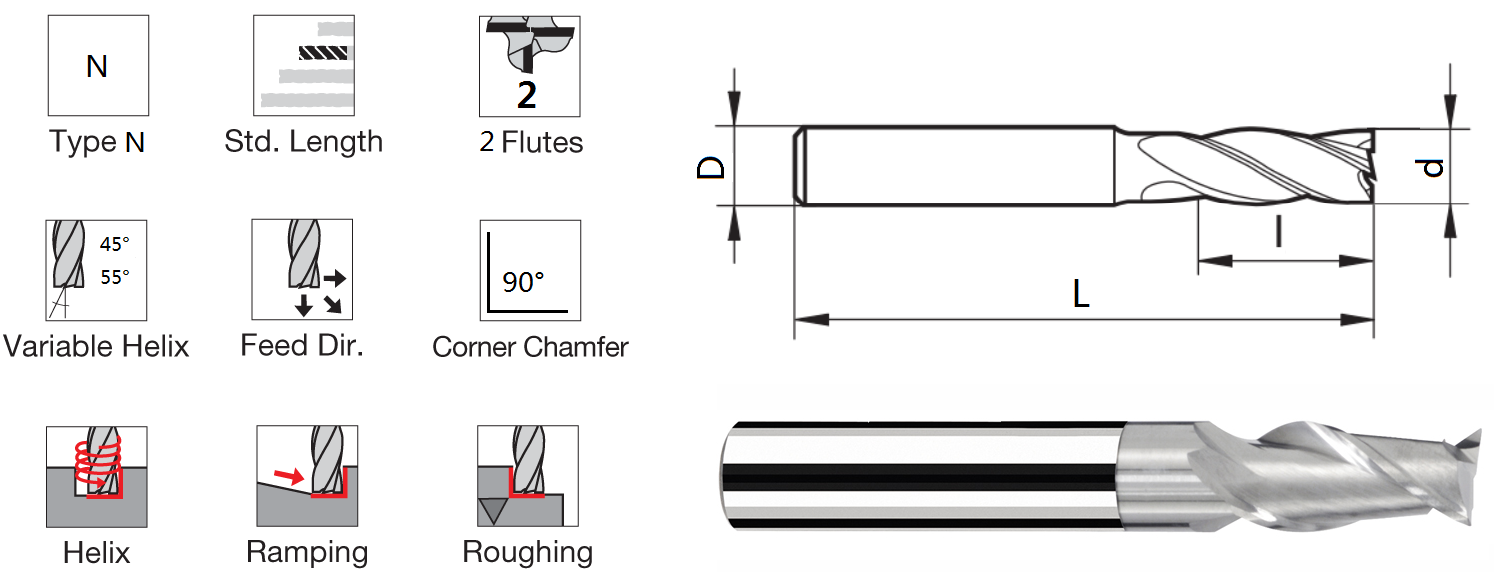

Chitoliro F2 F3

Mawu enieni:

Alumi-tech carbide end mphero amapangidwa makamaka kuti azigaya aluminiyamu ndi zitsulo zotayidwa. Zoyenera kugwiritsa ntchito slot ndi roughing, zida izi zimapezeka mumitundu iwiri kapena itatu ya zitoliro, zolimba komanso zoziziritsa kukhosi. Bright finish ndipo Super-groove grinded standard product ikupezeka kuchokera ku stock.

Mawonekedwe:

- Oyenera aluminium aloyi (Si≤12%) ndi aloyi yamkuwa (

Mphamvu zabwino kwambiri m'mphepete, kudzikonda kwabwino kwambiri

Milomo yowongoka, kukonzekera bwino m'mphepete kumasinthidwa, kulimbitsa mphamvu ya m'mphepete.

Nyumba yaying'ono yam'mphepete, taper yayikulu yakuda, kuchepetsa kukangana ndi kugunda kwa torque.

Kukula kokhazikika:

1. Ultrafine particles wa2 chitoliro zitsulo zomaliza za aluminiyamu

| Kuitanitsa kodi | Diameter | Kutalika kwa chitoliro | O.A.L. | Shank Dia. |

| HJA600-0302 | 3 | 9.0 | 50 | 3 |

| HJA600-0102 | 1 | 4.0 | 50 | 4 |

| HJA600-0152 | 1.5 | 5.0 | 50 | 4 |

| HJA600-0202 | 2 | 6.0 | 50 | 4 |

| HJA600-0252 | 2.5 | 7.0 | 50 | 4 |

| HJA600-0302 | 3 | 9.0 | 50 | 4 |

| HJA600-0352 | 3.5 | 10.0 | 50 | 4 |

| HJA600-0402 | 4 | 12.0 | 50 | 4 |

| HJA600-0502 | 5 | 15.0 | 50 | 5 |

| HJA600-0102 | 1 | 4.0 | 50 | 6 |

| HJA600-0152 | 1.5 | 5.0 | 50 | 6 |

| HJA600-0202 | 2 | 6.0 | 50 | 6 |

| HJA600-0302 | 3 | 9.0 | 50 | 6 |

| HJA600-0402 | 4 | 12.0 | 50 | 6 |

| HJA600-0502 | 5 | 15.0 | 50 | 6 |

| HJA600-0620 | 6 | 18.0 | 50 | 6 |

| HJA600-0802 | 8 | 20.0 | 60 | 8 |

| HJA600-1002 | 10 | 30.0 | 75 | 10 |

| HJA600-1202 | 12 | 30.0 | 75 | 12 |

| HJA600-1402 | 14 | 40.0 | 100 | 14 |

| HJA600-1602 | 16 | 40.0 | 100 | 16 |

| HJA600-I802 | 18 | 45.0 | 100 | 18 |

| HJA600-2002 | 20 | 45.0 | 100 | 20 |

2.Tinthu ting'onoting'ono ta 3 chitoliro chomaliza cha aluminiyamus

| Kuitanitsa kodi | Diameter | Kutalika kwa chitoliro | O.A.L. | Shank Dia. |

| HJA600-0303 | 3 | 9 | 50 | 3 |

| HJA600-0103 | 1 | 4 | 50 | 4 |

| HJA600-0153 | 1.5 | 5 | 50 | 4 |

| HJA600-0203 | 2 | 6.0 | 50 | 4 |

| HJA600-0253 | 2.5 | 7 | 50 | 4 |

| HJA600-0303 | 3 | 9 | 50 | 4 |

| HJA600-0353 | 3.5 | 10.0 | 50 | 4 |

| HJA600-0403 | 4 | 12 | 50 | 4 |

| HJA600-0503 | 5 | 15 | 50 | 5 |

| HJA600-0103 | 1 | 4 | 50 | 6 |

| HJA600-0153 | 1.5 | 5 | 50 | 6 |

| HJA600-0203 | 2 | 6 | 50 | 6 |

| HJA600-0253 | 2.5 | 7 | 50 | 6 |

| HJA600-0303 | 3 | 9 | 50 | 6 |

| HJA600-0403 | 4 | 12 | 50 | 6 |

| HJA600-0503 | 5 | 15 | 50 | 6 |

| HJA600-0603 | 6 | 18 | 50 | 6 |

| HJA600-0803 | 8 | 20 | 60 | 8 |

| HJA600-1003 | 10 | 30 | 75 | 10 |

| HJA600-1203 | 12 | 30 | 75 | 12 |

| HJA600-1403 | 14 | 40 | 100 | 14 |

| HJA600-1603 | 16 | 40 | 100 | 16 |

| HJA600-1803 | 18 | 45 | 100 | 18 |

| HJA600-2003 | 20 | 45 | 100 | 20 |

3.Tinthu ting'onoting'ono ta 3. aluminiyamu ya chitoliro chotalikitsa mphero

| Kuitanitsa kodi | Diameter | Kutalika kwa chitoliro | O.A.L. | Shank Dia. |

| HJA650-0303 | 3 | 9 | 50 | 3 |

| HJA650-0103 | 1 | 4 | 50 | 4 |

| HJA650-0153 | 1.5 | 5 | 50 | 4 |

| HJA650-0203 | 2 | 6.0 | 50 | 4 |

| HJA650-0253 | 2.5 | 7 | 50 | 4 |

| HJA650-0303 | 3 | 9 | 50 | 4 |

| HJA650-0353 | 3.5 | 10.0 | 50 | 4 |

| HJA650-0403 | 4 | 12 | 50 | 4 |

| HJA650-0503 | 5 | 15 | 50 | 5 |

| HJA650-0103 | 1 | 4 | 50 | 6 |

| HJA650-0153 | 1.5 | 5 | 50 | 6 |

| HJA650-0203 | 2 | 6 | 50 | 6 |

| HJA650-0253 | 2.5 | 7 | 50 | 6 |

| HJA650-0303 | 3 | 9 | 50 | 6 |

| HJA650-0403 | 4 | 12 | 50 | 6 |

| HJA650-0503 | 5 | 15 | 50 | 6 |

| HJA650-0603 | 6 | 18 | 50 | 6 |

| HJA650-0803 | 8 | 20 | 60 | 8 |

| HJA650-1003 | 10 | 30 | 75 | 10 |

| HJA650-1203 | 12 | 30 | 75 | 12 |

Kapangidwe ka zida:

1.Zinthu Zathupi:

A) Kuuma kwakukulu kuposa kapena kofanana ndi 92.8 HRA;

B) Kachulukidwe wamkulu kuposa kapena wofanana ndi 14.2 g/cm³;

C) TRS wamkulu kuposa kapena wofanana ndi 4200 N/mm²;

2.Zida zonse zopangira, zokutira zimagwiritsidwa ntchito ku Germany, Switzerland, zida zopangira;

Parameter ya ntchito:

| HJA600 End mill for aluminum operation parameter:HJA600-S2 | ||||||||||||

| HJA600 S2 For Aluminium Alloy- Side Milling | ||||||||||||

| Maphunziro | Chida mawonekedwe | Workpiece Material | Kucheka kuya | VC | Chida Diameter | 1 | 2 | 4 | 6 | 8 | 10 | 12 |

| S2 | (mm) | m/mphindi | (mm) | |||||||||

| HJA600 | lalikulu | Reflecta Cast aluminium alloy Si<12% | ap≤1.5D | 150(60-350) | Liwiro | 19000 | 16000 | 12000 | 10600 | 10000 | 9500 | 9300 |

| (min-1) | ||||||||||||

| ae≤0.2D | kuchuluka kwa chakudya | 760 | 950 | 1300 | 1380 | 1500 | 1900 | 2600 | ||||

| (mm/mphindi) | ||||||||||||

| Copper aloyi <HB200 | ap≤1.5D | 150 (60-350) | Liwiro | 19000 | 16000 | 12000 | 10600 | 10000 | 9500 | 9300 | ||

| (min-1) | ||||||||||||

| ae≤0.2D | kuchuluka kwa chakudya | 690 | 860 | 1180 | 1240 | 1340 | 1720 | 2340 | ||||

| (mm/mphindi) | ||||||||||||

Chenjerani:

Onetsetsani kuti chogwirira ntchito ndi makina okhazikika ndikugwiritsa ntchito chogwirizira molondola.

Chonde sinthani liwiro, chakudya ndi kudula kuya molingana ndi mikhalidwe yeniyeni yodulira.

Makhalidwe a mphero ndi a mphero yomaliza pomwe kutalika kwa chida kumakhala kosakwana 4*D(mill dia). Chida chikatalikirapo kutalika, chonde sinthani liwiro, chakudya ndi kudula kuya.

Kampaniyo ili ndi mzere wathunthu wa zida zopangira zida zopangira zida zopangira ufa, kupanga nkhungu, kukanikiza, kuponderezana, kugaya, kupaka ndi kupaka pambuyo pochiritsa. Imayang'ana pa kafukufuku ndi kusinthika kwa zinthu zoyambira, kapangidwe ka groove, kupanga molondola komanso zokutira pamwamba pa zoyikapo za carbide NC, ndipo nthawi zonse kumapangitsa kuti makina azigwira bwino ntchito, moyo wautumiki ndi zina zodulira zoyika za carbide NC. Pambuyo pazaka zopitilira khumi za kafukufuku wasayansi ndi luso, kampaniyo yadziwa zambiri zamaukadaulo odziyimira pawokha, ili ndi R&D yodziyimira payokha komanso luso lakapangidwe, ndipo imatha kupereka zopanga makonda kwa kasitomala aliyense.