Kusanthula kwapangidwe kwa zoyikapo simenti ya carbide

Monga momwe zilili ndi zinthu zonse zopangidwa ndi anthu, kupanga zitsulo zolemera zachitsulo ziyenera kuthetsa vuto la zipangizo, ndiko kuti, kudziwa kapangidwe kake ndi ndondomeko ya zipangizo zamasamba. Masamba ambiri amasiku ano amapangidwa ndi simenti ya carbide, yomwe imakhala ndi tungsten carbide (WC) ndi cobalt (Co). WC ndi tinthu tating'ono pa tsamba, ndipo Co angagwiritsidwe ntchito ngati binder kupanga tsamba.

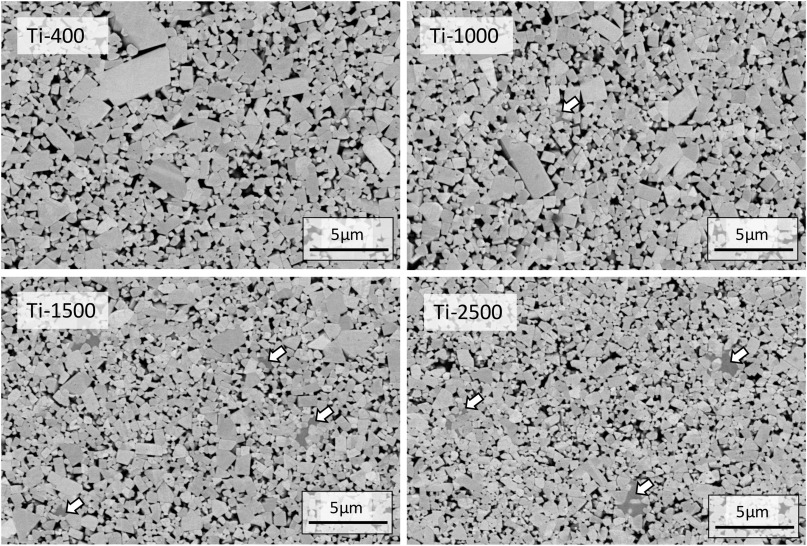

Njira yosavuta yosinthira mawonekedwe a simenti ya carbide ndikusintha kukula kwa tinthu tating'onoting'ono ta WC. Kukula kwa tinthu ting'onoting'ono (3-5 μ m) Kuuma kwa zinthu zopangira simenti zokonzedwa ndi tinthu tating'onoting'ono ta WC ndi C% ndizotsika komanso zosavuta kuvala; Tinthu tating'onoting'ono (< 1 μ m) Tinthu tating'onoting'ono ta WC titha kupanga zida zolimba za aloyi ndi kuuma kwakukulu, kukana kuvala bwino, komanso kuphulika kwakukulu. Pamene machining zipangizo zitsulo ndi mkulu kuuma, ntchito mbewu zabwino simenti carbide amaika angapeze zotsatira zabwino Machining. Kumbali inayi, chida cha carbide cholimba chambewu chimakhala ndi ntchito yabwino pakudula pang'onopang'ono kapena makina ena omwe amafunikira kulimba kwa chidacho.

Njira ina yowongolera mawonekedwe a zoyikapo simenti ya carbide ndikusintha gawo la WC kukhala Co content. Poyerekeza ndi WC, kuuma kwa Co ndikotsika kwambiri, koma kulimba kuli bwino. Chifukwa chake, kuchepetsa zomwe zili mu Co kumabweretsa kuuma kwakukulu. Zachidziwikire, izi zimadzutsanso vuto la kukhazikika bwino - masamba owuma kwambiri amakhala ndi kukana kovala bwino, koma brittleness yawo imakhalanso yayikulu. Malinga ndi mtundu wa kakonzedwe kameneka, kusankha makulidwe oyenera a tirigu a WC ndi chiŵerengero cha Co content kumafuna chidziwitso choyenera cha sayansi ndi luso lokonzekera bwino.

Pogwiritsa ntchito ukadaulo wazinthu zamtundu wa gradient, kusagwirizana pakati pa kulimba ndi kulimba kwa tsamba kumatha kupewedwa pamlingo wina. Tekinoloje iyi, yomwe yakhala ikugwiritsidwa ntchito kwambiri ndi opanga zida zazikulu padziko lonse lapansi, imaphatikizapo kugwiritsa ntchito chiŵerengero chapamwamba cha Co mumtundu wakunja kwa tsamba kusiyana ndi mkati. Mwachindunji, wosanjikiza wakunja wa tsamba (makhuthala 15-25 μ m) Wonjezerani Co okhutira kuti apereke ntchito yofanana ndi "buffer zone", kotero kuti tsambalo likhoza kupirira zovuta zina popanda kusweka. Izi zimathandiza chida thupi la tsamba kupeza zinthu zosiyanasiyana zabwino zomwe zingatheke pokhapokha pogwiritsa ntchito simenti carbide ndi mphamvu apamwamba.

Kamodzi tinthu kukula, zikuchokera ndi zina luso magawo zopangira anatsimikiza, kwenikweni kupanga ndondomeko kudula amaika akhoza anayamba. Choyamba, ikani ufa wa tungsten wofananira, ufa wa kaboni ndi ufa wa cobalt mu mphero yomwe ili yofanana ndi makina ochapira, perani ufawo mpaka kukula kofunikira, ndikusakaniza mitundu yonse ya zipangizo mofanana. Pa mphero, mowa ndi madzi amawonjezeredwa kuti akonze slurry wandiweyani wakuda. Kenako slurry amayikidwa mu chowumitsira mphepo yamkuntho, ndipo madzi mu slurry amasanduka nthunzi kuti apeze lumpy ufa ndikusungidwa.

Muzotsatira zokonzekera, chitsanzo cha tsamba chikhoza kupezeka. Choyamba, ufa wokonzeka umasakanizidwa ndi polyethylene glycol (PEG). Monga plasticizer, PEG imatha kulumikiza ufawo kwakanthawi ngati mtanda. Zinthuzo zimakanikizidwa mu mawonekedwe a tsamba mu kufa. Malinga ndi njira zosiyanasiyana zosindikizira masamba, makina osindikizira a single axis amatha kugwiritsidwa ntchito kukanikiza, kapena makina osindikizira ambiri angagwiritsidwe ntchito kukanikiza mawonekedwe a tsamba kuchokera kumakona osiyanasiyana.

Pambuyo kupeza mbamuikha akusowekapo, izo zimayikidwa mu ng'anjo yaikulu sintering ndi sintered pa kutentha kwambiri. M'kati mwa sintering, PEG imasungunuka ndikutulutsidwa kuchokera kusakaniza kwa billet, ndikusiya tsamba la carbide lopangidwa ndi theka lomaliza. PEG ikasungunuka, tsambalo limatsika mpaka kukula kwake * komaliza. Njirayi imafunikira kuwerengera kolondola kwa masamu, chifukwa kuchepa kwa tsamba ndi kosiyana malinga ndi zolemba zosiyanasiyana zakuthupi ndi ma ratios, ndipo kulolerana kwazinthu zomalizidwa kumafunika kuwongolera mkati mwa ma microns angapo.

Nthawi Yolemba: 2023-01-15