Why does the carbide blade break?

Causes and countermeasures of carbide blade breakage:

1. The blade brand and specification are improperly selected, such as the blade thickness is too thin or the rough machining is too hard and fragile.

Countermeasures: increase the thickness of the blade or install the blade in a vertical position, and select a brand with higher bending strength and toughness.

2. Improper selection of tool geometry parameters (such as excessive front and rear angles, etc.).

Countermeasures: The tools can be redesigned from the following aspects. (1) Reduce the front and rear angles appropriately; (2) Adopt large negative blade inclination; (3) Reduce the main deflection angle; (4) Use larger negative chamfer or cutting edge arc; (5) Grind the transition cutting edge to enhance the tool tip.

3. The welding process of the blade is incorrect, resulting in excessive welding stress or welding cracks.

Countermeasures: (1) Avoid using three-sided closed blade groove structure; (2) Correct selection of solder; (3) Avoid heating welding with oxyacetylene flame, and eliminate internal stress after thermal insulation welding; (4) Use mechanical clamping structure as far as possible

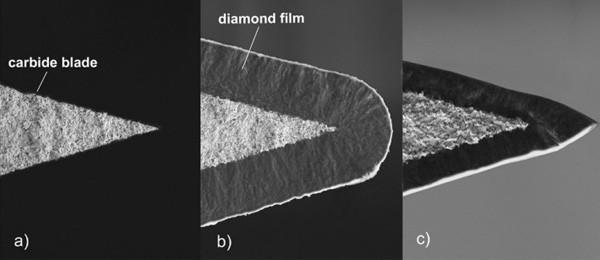

Tungsten carbide blade

4. Improper grinding method will cause grinding stress and grinding crack; Excessive vibration of the teeth after grinding PCBN milling cutter will cause excessive load on individual teeth, which will also lead to tool impact.

Countermeasures: (1) intermittent grinding or diamond grinding wheel grinding; (2) Choose soft wheels and wear them frequently to keep them sharp; (3) Pay attention to the grinding quality and strictly control the vibration of cutter teeth.

5. The selection of cutting amount is unreasonable. If the volume is too large, the machine will become sultry; During intermittent cutting, the cutting speed is too high, the feed speed is too high, the blank allowance is uneven, and the cutting depth is too small; Cutting high manganese steel is too slow for materials with high work-hardening tendency.

Countermeasures: reselect the cutting amount.

6. The bottom surface of the slot of the mechanical clamping tool is uneven or the blade is too long.

Countermeasures: (1) Trim the bottom surface of the tool groove; (2) Reasonably arrange the position of cutting fluid nozzle; (3) Add cemented carbide gasket under the blade of hardened tool rod.

7. The tool is excessively worn.

Countermeasures: replace the tool or cutting edge in time.

8. The cutting fluid flow is insufficient or the filling method is incorrect, resulting in the bursting and cracking of the blade.

Countermeasures: (1) Increase cutting fluid flow; (2) Reasonably arrange the position of cutting fluid nozzle; (3) Effective cooling methods such as spray cooling are adopted to improve the cooling effect.

9. The tool installation is incorrect, such as: the tool installation is too high or too low; The face milling cutter adopts asymmetric downward milling, etc.

Countermeasures: Reinstall the tool.

10. The rigidity of the process system is too poor, resulting in excessive cutting vibration.

Countermeasures: (1) Increase the auxiliary support of the workpiece to improve the rigidity of the workpiece clamping; (2) Reduce tool overhang; (3) Reduce the tool clearance angle properly; (4) Use other anti-vibration measures.

11. Unintentional operation, for example, when the tool cuts through the middle of the workpiece, the action is too violent; The tool has not been withdrawn and will stop immediately.

Countermeasures: pay attention to the operation method.

POST TIME: 2023-01-15