What is the Carbide Rotary File? How to solve the problems in the use of carbide rotary files?

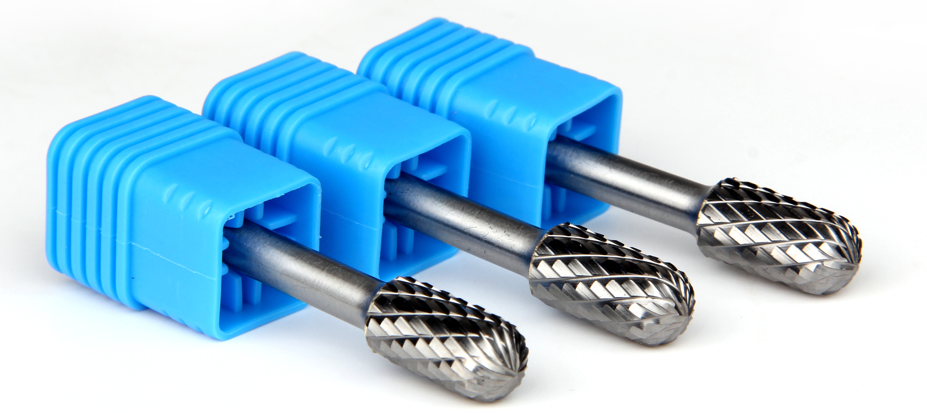

Carbide Rotary Burrs

Carbide rotary files, also known as carbide high-speed assorted milling cutters, carbide mold milling cutters, etc., are mainly driven by electric tools or pneumatic tools (and can also be installed on high-speed machine tools).

Introduction

It has a wide range of uses, especially in aviation, ships, automobiles, machinery, chemicals and other industrial sectors. It can be used to process cast iron, cast steel, carbon steel, alloy steel, stainless steel, hardened steel, copper and aluminum, etc. Since the rotary file is clamped on a high-speed rotating tool for manual control, the pressure and feed speed of the rotary file are determined by the service life and cutting effect of the tool

Advantage of huijin carbide rotary files

1. It can process metals such as cast iron, cast steel, carbon steel, alloy steel, stainless steel, copper, aluminum, and non-metals such as marble, jade, and bone.

2. Basically, it can replace the small grinding wheel with handle, and there is no dust pollution.

3. High efficiency. The processing efficiency is dozens of times higher than that of manual files, and nearly ten times higher than that of small grinding wheels with handles.

4. Good processing quality and high finish. It can process various high-precision shape mold cavities.

5. Long service life. The durability is ten times higher than that of high-speed steel tools, and more than 200 times higher than that of small grinding wheels.

6. Easy to use, safe and reliable.

7. The use efficiency is high, and the comprehensive processing cost can be reduced by dozens of times.

When using carbide burrs, the following steps need to be followed:

1. Select the appropriate rotary file, as well as the appropriate speed and pressure according to the material and hardness of the workpiece to be processed.

2. Clamp the rotary file on the electric tool or air tool, clamp and ensure that the clamp is correct.

3. Fix the workpiece on the table and make sure that the clamping is firm.

4. When starting rotary processing, it is necessary to keep the cutting direction from right to left, avoid using the rotary file stuck in the groove or gap, and do not use the rotary file to twist or twist the workpiece.

5. Pay attention to safety during use, and wear suitable protective glasses to prevent the rotary file from flying out and hurting people.

6. After processing, remove the rotary file from the electric tool or air tool, clean and store it.

It should be noted that the carbide rotary file has high hardness and wear resistance, but it is also relatively brittle and easy to break or break. Therefore, special care is required during use to avoid shock or excessive pressure. At the same time, it is necessary to control the speed and pressure during processing to avoid vibration and overheating.

Carbide rotary files often have the following problems during use:

1. The processing accuracy is not high: the processing accuracy of the carbide rotary file is affected by many factors, such as speed, pressure, cutting direction, etc. If the processing accuracy is not high, it may be caused by improper control of the above factors.

2. Poor machining surface quality: The machining surface quality of cemented carbide rotary files is affected by many factors, such as material hardness, rotation speed, feed speed, etc. If the machined surface quality is poor, it may be caused by improper control of the above factors.

3. The rotary file is damaged or cracked: the carbide rotary file has high hardness and wear resistance, but is relatively brittle and easy to break or break. If the burr is damaged or chipped, it may have been caused by shock or excessive stress.

4. Vibration and overheating: Improper control of the speed and pressure of the carbide rotary file can easily lead to vibration and overheating, affecting the processing effect and service life.

For the above problems, the following solutions can be adopted:

1. Adjust the speed and pressure, control the cutting direction, and improve the machining accuracy and surface quality.

2. Select the appropriate cutting speed and feed rate, control the cutting depth and allowance, reduce tool wear and improve processing efficiency.

3. Strengthen the skill training of operators, avoid wrong operation and brutal operation, and reduce the damage and cracking of rotary files.

4. Regularly check and maintain electric tools or air tools to ensure their normal operation, avoid vibration and overheating.

If you need carbide burrs, or encounter any problems in the use of carbide burrs, please feel free to contact us. We provide you with a professional and perfect carbide rotary file solution.

POST TIME: 2023-05-23