Composition analysis of cemented carbide inserts

As with all man-made products, the manufacturing of cast iron heavy cutting blades should first solve the problem of raw materials, that is, determine the composition and formula of the blade materials. Most of today's blades are made of cemented carbide, which is mainly composed of tungsten carbide (WC) and cobalt (Co). WC is a hard particle in the blade, and Co can be used as a binder to shape the blade.

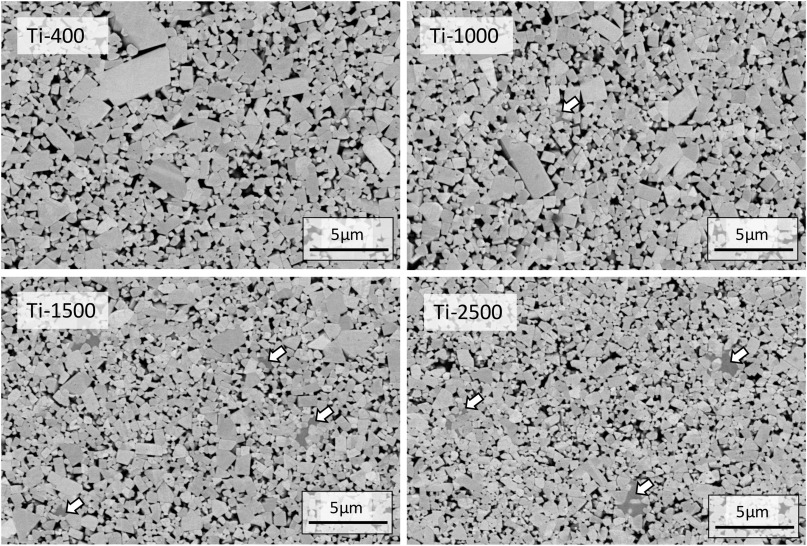

A simple way to change the properties of cemented carbide is to change the grain size of WC particles used. Large particle size (3-5 μ m) The hardness of cemented carbide material prepared by WC particles with C% is low and easy to wear; Small particle size (< 1 μ m) WC particles can produce hard alloy materials with higher hardness, better wear resistance, but also greater brittleness. When machining metal materials with very high hardness, the use of fine grain cemented carbide inserts may achieve ideal machining results. On the other hand, the coarse grain cemented carbide tool has better performance in intermittent cutting or other machining that requires higher toughness of the tool.

Another way to control the characteristics of cemented carbide inserts is to change the proportion of WC to Co content. Compared with WC, the hardness of Co is much lower, but the toughness is better. Therefore, reducing the content of Co will result in a higher hardness blade. Of course, this once again raises the problem of comprehensive balance - higher hardness blades have better wear resistance, but their brittleness is also greater. According to the specific processing type, selecting the appropriate WC grain size and Co content ratio requires relevant scientific knowledge and rich processing experience.

By using gradient material technology, the compromise between the strength and toughness of the blade can be avoided to some extent. This technology, which has been widely used by the world's major tool manufacturers, includes the use of a higher Co content ratio in the outer layer of the blade than in the inner layer. More specifically, the outer layer of the blade (thickness 15-25 μ m) Increase Co content to provide a function similar to "buffer zone", so that the blade can withstand a certain impact without cracking. This enables the tool body of the blade to obtain various excellent properties that can be achieved only by using cemented carbide with higher strength.

Once the particle size, composition and other technical parameters of raw materials are determined, the actual manufacturing process of cutting inserts can be started. First, put the matching tungsten powder, carbon powder and cobalt powder into a mill that is about the same size as the washing machine, grind the powder to the required particle size, and mix all kinds of materials evenly. During the milling process, alcohol and water are added to prepare a thick black slurry. Then the slurry is put into a cyclone dryer, and the liquid in the slurry is evaporated to obtain lumpy powder and stored.

In the next preparation process, the prototype of the blade can be obtained. First, the prepared powder is mixed with polyethylene glycol (PEG). As a plasticizer, PEG can temporarily bond the powder together like dough. The material is then pressed into the shape of a blade in a die. According to different blade pressing methods, single axis press can be used for pressing, or multi axis press can be used to press the blade shape from different angles.

After obtaining the pressed blank, it is placed in a large sintering furnace and sintered at high temperature. In the sintering process, PEG is melted and discharged from the billet mixture, leaving a semi-finished cemented carbide blade. When PEG is melted out, the blade shrinks to its * final size. This process step requires accurate mathematical calculation, because the shrinkage of the blade is different according to different material compositions and ratios, and the dimensional tolerance of the finished product is required to be controlled within several microns.

POST TIME: 2023-01-15