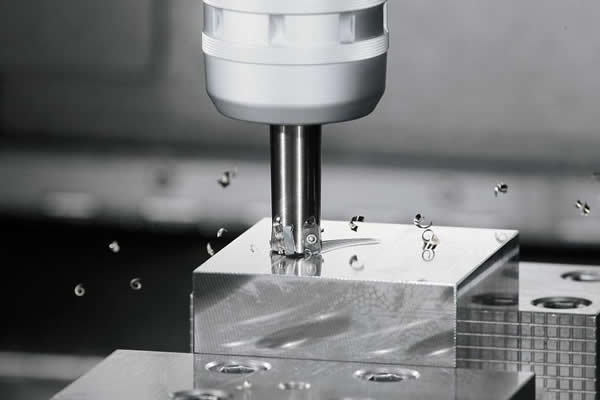

Classification and structure of milling cutter

1、 Classification of CNC milling cutter

(1) According to the materials used for manufacturing milling cutter, it can be divided into

1。 High speed steel cutter;

2。 Carbide cutter;

3。 Diamond tools;

4。 Tools made of other materials, such as cubic boron nitride tools, ceramic tools, etc.

(2) It can be divided into

1. Integral type: the tool and the handle are made into a whole.

2. Inlaid type: it can be divided into welding type and machine clamp type.

3. When the ratio of the working arm length to the diameter of the tool is large, in order to reduce the vibration of the tool and improve the machining accuracy, this kind of tool is often used.

4. Internal cooling type: cutting fluid is sprayed to the cutting edge of the tool through the nozzle inside the tool body;

5. Special types: such as composite tools, reversible thread tapping tools, etc.

3) It can be divided into

1. Face milling cutter (also called End milling cutter): there are cutting edges on the circular surface and end face of the face milling cutter, and the end cutting edge is a secondary cutting edge. The face milling cutter is mostly made of sleeve type inserted gear structure and indexable structure of the cutter holder. The cutter teeth are made of high speed steel or hard alloy, and the cutter body is 40CR. Drilling tools, including drills, reamers, taps, etc;

2. Die milling cutter: Die milling cutter is developed from end milling cutter. It can be divided into three types: conical end milling cutter, cylindrical ball end milling cutter and conical ball end milling cutter. Its shank has straight shank, flat straight shank and Morse taper shank. Its structural feature is that the ball head or end face is covered with cutting edges, the circumferential edge is connected with the arc of the ball head edge, and can be used for radial and axial feed. The working part of the milling cutter is made of high-speed steel or hard alloy. Aluminum plate spot welder

3. Keyway milling cutter: used for milling keyways.

4. Form milling cutter: the cutting edge is consistent with the shape of the surface to be machined.

POST TIME: 2023-01-15