Classification and function of turning tools

There are also many cutting tools in our life. For example, knives, kitchen knives and other cutting tools in the kitchen and Ca chopping boards (for cleaning radish) are all cutting tools. Also, paper cutters and pencil sharpeners on the table, saws and planers in the toolbox, etc. are also cutting tools. What these tools have in common is that they can change the shape of objects and generate cutting chips by cutting and cutting., A cutting tool is a tool that makes an object close to the desired shape by cutting. The cutting tools in our life are used to process fruits, vegetables and wood, and the cutting tools are used to process materials such as iron that are harder than them.

Cutting tool manufacturing process

Firstly, tungsten carbide and cobalt are mixed to make raw material powder, and the raw material powder is put into a mold for stamping to make it have the hardness similar to that of chalk. Then sinter at 1400 °. In this way, the cemented carbide is made. Cemented carbide has such a feature that its volume becomes half of the original after sintering. The hardness of cemented carbide is between diamond and sapphire, and its weight is nearly twice that of iron. Here, how to process such hard cemented carbide? Diamond grinding wheel is used for grinding to make it a desired shape.

Cutting process

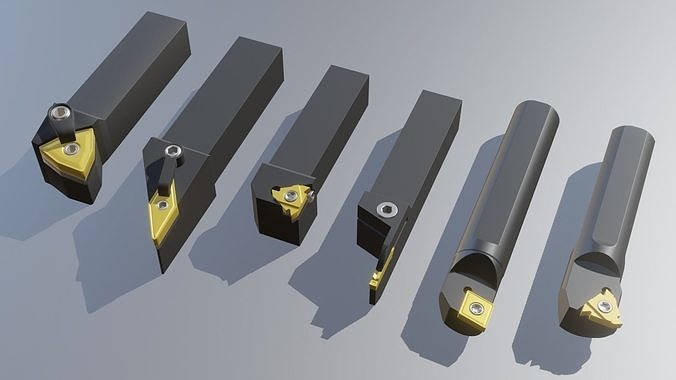

The state of the cutting edge in the cutting process. When the material touches the cutting tool, it breaks off and becomes chips. At this time, the heat generated sometimes reaches more than 800 degrees. In this cutting process, the tool tip will be strongly impacted and generate high heat. Cemented carbide with strong bearing capacity in these aspects is the main force of modern tool materials. Such blades can be installed on various tool holders, and can also be selected according to the shape of the workpiece and the cutting method. We call this cutting edge indexable blade, which has become the mainstream of cemented carbide tools in the form of replaceable tip.

What is turning

Tools for cutting cylindrical objects include turning tools for outer diameter and boring tools for inner diameter. The cutting process with turning tool and boring tool is called turning process, and the rotation of workpiece is the feature of turning process. It mainly refers to the rotation of the workpiece. The machine tool that processes the workpiece into a circle is called a lathe.

POST TIME: 2023-01-15