- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

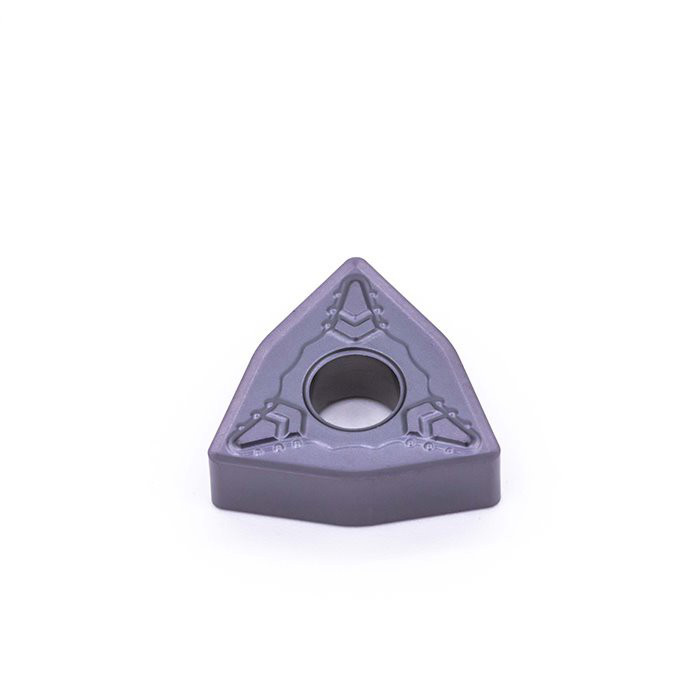

Metal Schneid Inserts

Metal Schneid Inserts

Produit Numm: Metal Cutting Inserts

Serie: WNMG Turning Inserts

Chip-Breakers: AM/AR/BF/BM/BR/CM/DM/

Produkt Informatioun:

WNMG Turning Inserts 80 ° Insert doppelseiteg Inserts mat negativen (0 °) Reliefwénkel, bitt e staarke Rand fir allgemeng Uwendungen a variéiert Schnëttdéiften ofhängeg vum Chipbreaker Typ iwwer déi meescht Materialien. WNMG Turning Inserts can deal with multiple operations by combining different chip breakers and grades.it ass héich ekonomesch Wiel fir Är Produktioun, well se symmetresch gemaach ginn, sou datt wann déi eng Schneidekant gedroen ass, se op eng aner Kante rotéiere kënnen.

Spezifikatioune:

Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK4235 | JK4335 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | ||||

P Semi Finishing | WNMG080404-AM | 0.60-4.30 | 0.10-0.30 | • | O | • | O | O | |||||||

WNMG080408-AM | 1.20-4.30 | 0.20-0.60 | • | O | • | O | O | ||||||||

WNMG080412-AM | 1.80-4.30 | 0.30-0.90 | • | O | • | O | O | ||||||||

WNMG080416-AM | 2.40-4.30 | 0.40-1.20 | • | O | • | O | O | ||||||||

• : Recommandéiert Grad

O: Optional Grad

| Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4215 | JK4225 | JK4325 | JK4235 | JK4335 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | ||||

P Rau Machining | WNMG060408-AR | 0.80-4.00 | 0.15-0.50 | • | O | ||||||||||

WNMG060412-AR | 0.80-4.00 | 0.15-0.50 | • | O | |||||||||||

WNMG080408-AR | 0.80-4.50 | 0.15-0.55 | • | O | |||||||||||

WNMG080412-AR | 0.80-4.50 | 0.20-0.55 | • | O | |||||||||||

• : Recommandéiert Grad

O: Optional Grad

| Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | JR1525 | JR1330 | ||||

M Ofschloss | WNMG060404-BF | 0.25-2.40 | 0.05-0.15 | • | • | O | O | ||||||||

WNMG060408-BF | 0.50-2.40 | 0.10-0.30 | • | • | O | O | |||||||||

WNMG080404-BF | 0.25-3.20 | 0.05-0.15 | • | • | O | O | |||||||||

WNMG080408-BF | 0.50-3.20 | 0.10-0.30 | • | • | O | O | |||||||||

WNMG080412-BF | 0.75-3.20 | 0.15-0.45 | • | • | O | O | |||||||||

WNMG080416-BF | 1.05-3.20 | 0.20-0.60 | • | • | O | O | |||||||||

• : Recommandéiert Grad

O: Optional Grad

| Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | JR1525 | JR1330 | ||||

M Semi Finishing | WNMG060404-BM | 0.30-2.10 | 0.10-0.30 | O | O | • | O | O | |||||||

WNMG060408-BM | 0.65-2.10 | 0.15-0.45 | O | O | • | O | O | ||||||||

WNMG080404-BM | 0.30-2.90 | 0.10-0.30 | O | O | • | O | O | ||||||||

WNMG080408-BM | 0.65-2.90 | 0.15-0.45 | O | O | • | O | O | ||||||||

WNMG080412-BM | 0.95-2.90 | 0.20-0.60 | O | O | • | O | O | ||||||||

WNMG080416-BM | 1.25-2.90 | 0.25-0.75 | O | O | • | O | O | ||||||||

• : Recommandéiert Grad

O: Optional Grad

| Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | JR1528 | JR1330 | ||||

M Rau Machining | WNMG060404-BR | 0.30-2.10 | 0.10-0.30 | O | O | O | • | • | O | ||||||

WNMG060408-BR | 0.65-2.10 | 0.15-0.45 | O | O | O | • | • | O | |||||||

WNMG080404-BR | 0.30-2.90 | 0.10-0.30 | O | O | O | • | • | O | |||||||

WNMG080408-BR | 0.65-2.90 | 0.15-0.45 | O | O | O | • | • | O | |||||||

WNMG080412-BR | 0.95-2.90 | 0.20-0.60 | O | O | O | • | • | O | |||||||

WNMG080416-BR | 1.25-2.90 | 0.25-0.75 | O | O | O | • | • | O | |||||||

• : Recommandéiert Grad

O: Optional Grad

| Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | |||

CVD | |||||||

JK3020 | JK3040 | JK3315 | JK3415 | ||||

K Semi Finishing | WNMG080404-CM | 0.08-0.25 | 0.40-2.90 | • | • | ||

WNMG080408-CM | 0.15-0.45 | 0.80-2.90 | • | • | |||

WNMG080412-CM | 0.25-0.66 | 1.20-2.90 | • | • | |||

• : Recommandéiert Grad

O: Optional Grad

| Applikatioun | Typ | Ap (mm) | Fn (mm/v) | Grad | ||||||||||||

| CVD | PVD | |||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1520 | JR1525 | JR1028 | JR1330 | ||||

S Semi Finishing | WNMG080404-DM | 0.40-4.30 | 0.08-0.25 | O | O | O | • | • | O | O | ||||||

WNMG080408-DM | 0.80-4.30 | 0.15-0.45 | O | O | O | • | • | O | O | |||||||

WNMG080412-DM | 1.20-4.30 | 0.25-0.66 | O | O | O | • | • | O | O | |||||||

WNMG080416-DM | 1.60-4.30 | 0.30-0.90 | O | O | O | • | • | O | O | |||||||

• : Recommandéiert Grad

O: Optional Grad

Applikatioun:

Dës WNMG Turning Inserts kënne mat multiple Operatiounen ëmgoen andeems verschidde Chipbrecher a Graden kombinéiert ginn. Recommandéiert fir rau, semi-finishing an Ofbau vun machining meeschte Stol, STAINLESS Stol, Goss an super Legierungen ënner stabile Konditiounen.

D'Firma huet eng komplett Blade Fabrikatioun Prozess Ausrüstung Produktioun Linn aus Pudder Rohmaterial Virbereedung, Ofdréck maachen, Pressen, Drock sinteren, Schleifen, Beschichtung a Beschichtung Post-Behandlung. Et konzentréiert sech op d'Fuerschung an d'Innovatioun vum Basismaterial, d'Groovestruktur, d'Präzisiounsformung an d'Uewerflächbeschichtung vu Carbide NC-Inserts, a verbessert permanent d'Maschinneffizienz, Liewensdauer an aner Schneideigenschaften vun Carbide NC-Inserts. No méi wéi zéng Joer wëssenschaftlech Fuerschung an Innovatioun, huet d'Firma eng Rei vun onofhängege Kär Technologien beherrscht, huet onofhängeg R & D an Design Kënnen, a kann personaliséiert Produktioun fir all Client bidden.