- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

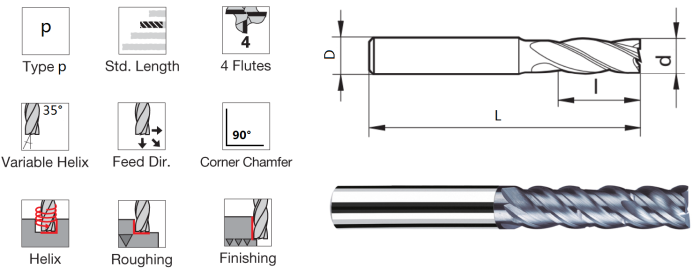

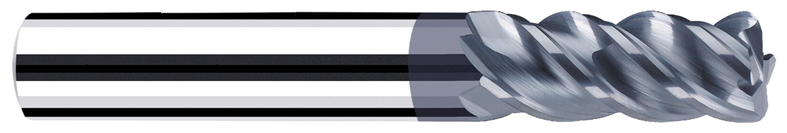

F4 F2 H Optimized End Mill kanggo Hardened Steels

End Mill kanggo Hardened Steels (48-60 HRC)

HJMJ600 End Mill kanggo Hardened Steels (48-60 HRC)

aplikasi: Kanggo hardened steels (48-60 HRC) pagawean.

Universal High Performance Coating AlCrSiN

F4 F2

Pranyatan literal:

End mill for die digunakake sacara wiyar, bisa dipasang lan digunakake ing piranti pneumatik utawa listrik, efisiensi produksi lan daya tahan tinimbang roda nggiling lan nambah kaping pirang-pirang file.

Fitur:

1. High atose, bahan matriks kateguhan dhuwur, desain amba khusus lan perawatan pinggiran, khusus kanggo hardened steels professing.

2. Kanggo hardened steels (48-60 HRC) finishing.

3. Dianjurake kanggo nggunakake online utawa lenga kedhul cooling.

Ukuran biasa:

1.4 Flute End Mills

| Kode pesenan | Diameter njaba | Suling Panjang | Sakabèhé dawa | Diameter Shank |

| (d) | (L) | (D) | ||

| HJMJ600-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJMJ600-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJMJ600-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJMJ600-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJMJ600-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJMJ600-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJMJ600-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJMJ600-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJMJ600-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJMJ600-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJMJ600-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJMJ600-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJMJ600-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJMJ600-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJMJ600-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJMJ600-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJMJ600-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJMJ600-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJMJ600-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

2. 2 Flute Corner Radius End Mills

| Diameter njaba | R | Suling Panjang | Sakabèhé dawa | Diameter Shank | |

| (d) | (l) | (L) | (D) | ||

| HJMJ600-2F-010-02 | 1 | 0.2 | 2 | 50 | 4 |

| HJMJ600-2F-015-02 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ600-2F-015-03 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ600-2F-020-02 | 2 | 0.2 | 4 | 50 | 4 |

| HJMJ600-2F-020-05 | 2 | 0.5 | 4 | 50 | 4 |

| HJMJ600-2F-025-02 | 2.5 | 0.2 | 5 | 50 | 4 |

| HJMJ600-2F-025-05 | 2.5 | 0.5 | 5 | 50 | 4 |

| HJMJ600-2F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ600-2F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ600-2F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ600-2F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ600-2F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ600-2F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ600-2F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ600-2F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ600-2F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ600-2F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ600-2F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ600-2F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ600-2F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ600-2F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ600-2F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ600-2F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ600-2F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ600-2F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ600-2F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ600-2F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ600-2F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ600-2F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ600-2F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ600-2F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ600-2F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ600-2F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ600-2F-120-20 | 12 | 20 | 24 | 75 | 12 |

| HJMJ600-2F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ600-2F-120-30 | 12 | 3 | 24 | 75 | 12 |

3.4 Suling Corner Radius End Mills

| Diameter njaba | R | Suling Panjang | Sakabèhé dawa | Diameter Shank | |

| (d) | (l) | (L) | (D) | ||

| HJMJ600-4F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ600-4F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ600-4F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ600-4F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ600-4F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ600-4F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ600-4F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ600-4F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ600-4F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ600-4F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ600-4F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ600-4F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ600-4F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ600-4F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ600-4F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ600-4F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ600-4F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ600-4F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ600-4F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ600-4F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ600-4F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ600-4F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ600-4F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ600-4F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ600-4F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ600-4F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ600-4F-120-20 | 12 | 2 | 24 | 75 | 12 |

| HJMJ600-4F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ600-4F-120-30 | 12 | 3 | 24 | 75 | 12 |

Komposisi bahan alat

Universal High Performance Coating AlCrSiN

Karakteristik lan Fungsi

1, Tambah produktivitas amarga kacepetan nglereni Ngartekno luwih lan feed kanggo aplikasi ing sawetara saka sudhut materials.Significantly meningkat produktivitas.

2, desain tartamtu saka struktur ndadekke imbangan apik antarane kateguhan, stabilitas thermo-kejut lan kaku ampas.

Parameter operasi:

| HJMJ600End mill for die Operation parameter: | |||||||||||

| HJMJ600-S4 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||

| biji | Wangun piranti | Bahan kerja | Nglereni jero | VC | Diameter alat | 2 | 4 | 6 | 8 | 10 | 12 |

| S4 | (mm) | m/min | (mm) | ||||||||

| HJMJ600 | Square, jari-jari pojok | HRC58 | ap≤1D | 120 | Speed(min-1) | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 |

| ae≤0.05D | Kacepetan feed | 760 | 760 | 760 | 760 | 730 | 710 | ||||

| (mm/min) | |||||||||||

| HRC58-62 | ap≤0.7D | 90 | Kacepetan | 15920 | 11940 | 7960 | 5970 | 4780 | 3980 | ||

| (min-1) | |||||||||||

| ae≤0.03D | Kacepetan feed | 510 | 720 | 730 | 720 | 730 | 670 | ||||

| (mm/min) | |||||||||||

manungsa waé:

Priksa manawa piranti lan mesin stabil lan gunakake wadhah presisi.

Mangga nyetel kacepetan, feed lan ambane nglereni miturut kahanan nglereni nyata.

Kondhisi penggilingan yaiku kanggo gilingan pungkasan sing dawane overhang alat kurang saka 4 * D (diameter pabrik). Yen dawa overhang alat luwih dawa, atur kacepetan, feed lan ambane nglereni.

Perusahaan kasebut nduweni lini produksi peralatan proses manufaktur blade lengkap saka persiapan bahan baku bubuk, nggawe cetakan, pressing, sintering tekanan, grinding, lapisan lan lapisan sawise perawatan. Fokus ing riset lan inovasi saka materi dhasar, struktur alur, tliti mbentuk lan nutupi lumahing carbide NC sisipan, lan saya mbenakake efficiency mesin, urip layanan lan situs nglereni liyane carbide NC sisipan. Sawise luwih saka sepuluh taun riset ilmiah lan inovasi, perusahaan wis nguwasani sawetara teknologi inti sawijining, duwe R&D lan kemampuan desain sawijining, lan bisa nyedhiyani produksi selaras kanggo saben customer.