- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

F4 F2 Ọgwụgwụ igwe maka igwe siri ike

Ọgwụgwụ igwe maka igwe siri ike (65 HRC)

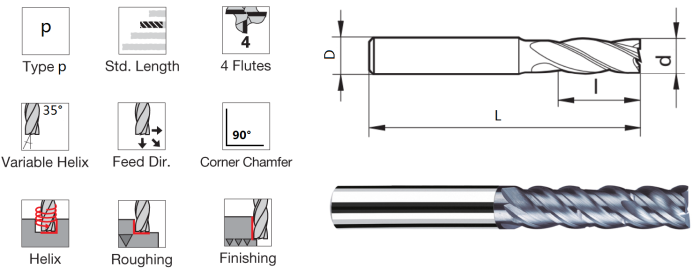

Usoro HJS650 - Ọgwụgwụ igwe maka igwe siri ike (65 HRC)

Kwesịrị ekwesị maka Semi-Finishing na Mmecha nke 62-68HRC Steels Hardened.

Ihe mkpuchi arụmọrụ dị elu zuru ụwa ọnụ AlCrSiN

F4 F2

Okwu nkịtị:

A na-eji igwe ihe igwe ngwụcha maka anwụ na-ejikarị, enwere ike itinye ya ma jiri ya mee ihe na pneumatic ma ọ bụ ngwa eletriki, arụmọrụ mmepụta yana ịdịte aka karịa igwe egweri wee na-abawanye ọnụ ọgụgụ nke ugboro faịlụ.

Atụmatụ:

Kwesịrị ekwesị maka Semi-Finishing na Mmecha nke 62-68HRC Steels Hardened.

Ike dị elu, ihe dị elu matriks ihe siri ike nke nwere mkpuchi emepụtara ọhụrụ, na-agbatị ndụ ngwaọrụ ahụ nke ukwuu

Akwadoro ka iji ikuku ma ọ bụ alụlụ mmanụ jụrụ oyi.

Nha oge niile:

1.4 Mills End Flute

Koodu ịtụ ahịa Koodu ịtụ ahịa | Dayameta dị n'èzí | Ogologo ọjà | Ogologo n'ozuzu | Dayameta Shank |

| (d) | (l) | (L) | (D) | |

| HJMJ650-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJMJ650-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJMJ650-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJMJ650-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJMJ650-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJMJ650-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJMJ650-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJMJ650-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJMJ650-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJMJ650-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJMJ650-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJMJ650-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJMJ650-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJMJ650-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJMJ650-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJMJ650-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJMJ650-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJMJ650-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJMJ650-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

2. 2 Flute Corner Radius End mills

| Dayameta dị n'èzí | R | Ogologo ọjà | Ogologo n'ozuzu | Dayameta Shank | |

| (d) | (l) | (L) | (D) | ||

| HJMJ650-2F-010-02 | 1 | 0.2 | 2 | 50 | 4 |

| HJMJ650-2F-015-02 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ650-2F-015-03 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ650-2F-020-02 | 2 | 0.2 | 4 | 50 | 4 |

| HJMJ650-2F-020-05 | 2 | 0.5 | 4 | 50 | 4 |

| HJMJ650-2F-025-02 | 2.5 | 0.2 | 5 | 50 | 4 |

| HJMJ650-2F-025-05 | 2.5 | 0.5 | 5 | 50 | 4 |

| HJMJ650-2F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ650-2F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ650-2F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ650-2F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ650-2F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ650-2F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ650-2F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ650-2F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ650-2F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ650-2F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ650-2F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ650-2F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ650-2F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ650-2F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ650-2F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ650-2F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ650-2F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ650-2F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ650-2F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ650-2F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ650-2F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ650-2F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ650-2F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ650-2F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ650-2F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ650-2F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ650-2F-120-20 | 12 | 20 | 24 | 75 | 12 |

| HJMJ650-2F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ650-2F-120-30 | 12 | 3 | 24 | 75 | 12 |

3.4 Flute Corner Radius End Mills

| Dayameta dị n'èzí | R | Ogologo ọjà | Ogologo n'ozuzu | Dayameta Shank | |

| (d) | (l) | (L) | (D) | ||

| HJMJ650-4F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ650-4F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ650-4F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ650-4F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ650-4F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ650-4F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ650-4F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ650-4F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ650-4F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ650-4F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ650-4F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ650-4F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ650-4F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ650-4F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ650-4F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ650-4F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ650-4F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ650-4F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ650-4F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ650-4F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ650-4F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ650-4F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ650-4F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ650-4F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ650-4F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ650-4F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ650-4F-120-20 | 12 | 2 | 24 | 75 | 12 |

| HJMJ650-4F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ650-4F-120-30 | 12 | 3 | 24 | 75 | 12 |

Ngwa ihe mejupụtara:

1. Njirimara anụ ahụ:

A) isi ike karịrị 94 HRA;

B) Njupụta karịrị ma ọ bụ hà nhata 14.6g/cm³;

C) TRS karịrị ma ọ bụ hà nhata 4100 N/mm²;

D) Enweghị ọnọdụ usoro ETA;

E) Ọnweghị mmetọ nke ihe ndị ọzọ;

F) Porosity = A00/ B00 / C00 ;

G) Ụdị na nha ọka na-agbanwe agbanwe. Ọ nweghị nha ọka nwere ike ibu karia akọwapụtara.

H) Chromium carbide naanị ihe mgbochi uto ọka.

2.A na-eji ngwá ọrụ niile nke mmepụta ihe, mkpuchi na Germany, Switzerland, ngwá ọrụ nhazi;

3.Ọ tụrụ aro ịcha ihe na-erughị 65HRC;

Mkpuchi:

Ihe mkpuchi arụmọrụ dị elu zuru ụwa ọnụ AlCrSiN

Njirimara na Ọrụ

1, Productivity abawanye n'ihi budata elu ọnwụ ọsọ na ndepụta maka ngwa na a dịgasị iche iche nke material.Significantly enwekwukwa arụpụtaghị ihe.

2, Particular imewe nke Ọdịdị na-eweta ezi itule n'etiti toughness, thermo-ujo kwụsie ike na mmapụta nchegbu.

Oke ọrụ:

| HJMJ650 End mill for die Operation parameter: | |||||||||||||

| HJMJ650-S2 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||||

| akara ule | Ụdị ngwaọrụ | Ihe eji arụ ọrụ | Omimi | VC | Dayameta Ngwá Ọrụ | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S2 | (mm) | m/min | (mm) | ||||||||||

| HJMJ650 | Square, akụkụ radius | Alloy mechie steel HRC65 | ap≤1D | 120 | Ọsọ | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 | 2390 | 1910 |

| (min-1) | |||||||||||||

| ae≤0.05D | Ọsọ nri | 380 | 380 | 380 | 380 | 370 | 360 | 310 | 290 | ||||

| (mm/min) | |||||||||||||

| HJMJ650End mill for die Operation parameter: | |||||||||||

| HJMJ650-S4 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||

| akara ule | Ụdị ngwaọrụ | Ihe eji arụ ọrụ | Omimi (mm) | VC | Dayameta Ngwá Ọrụ | 2 | 4 | 6 | 8 | 10 | 12 |

| S4 | m/min | (mm) | |||||||||

| HJMJ650 | Square, radius nkuku | HRC58-62 | ap≤1D | 120 | Ọsọ | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 |

| (min-1) | |||||||||||

| ae≤0.05D | Ọsọ nri | 760 | 760 | 760 | 760 | 730 | 710 | ||||

| (mm/min) | |||||||||||

| HRC68 | ap≤0.7D | 90 | Ọsọ | 15920 | 11940 | 7960 | 5970 | 4780 | 3980 | ||

| (min-1) | |||||||||||

| ae≤0.03D | Ọsọ nri | 510 | 720 | 730 | 720 | 730 | 670 | ||||

| (mm/min) | |||||||||||

Nlebara anya:

Gbaa mbọ hụ na mpempe ọrụ na igwe kwụsiri ike wee jiri njide ziri ezi.

Biko mezie ọsọ, nri na igbutu omimi dị ka ọnọdụ ịkpụ n'ezie.

Igwe ihe igwe nri bụ maka igwe igwe ngwụcha ebe ogologo ngwaọrụ karịrị erughị 4*D (mill dia). Mgbe ogologo overhang ngwá ọrụ dị ogologo, biko gbanwee ọsọ, nri na igbutu omimi.

The ụlọ ọrụ nwere zuru ezu agụba n'ichepụta usoro akụrụngwa mmepụta akara si ntụ ntụ akụrụngwa nkwadebe, ebu ime, ịpị, sintering nrụgide, egweri, mkpuchi na mkpuchi post-ọgwụgwọ. Ọ na-elekwasị anya na nyocha na ọhụrụ nke isi ihe, uzo Ọdịdị, nkenke akpụ na elu mkpuchi nke carbide NC inserts, na mgbe niile mma machining arụmọrụ, ọrụ ndụ na ndị ọzọ ọnwụ Njirimara nke carbide NC inserts. Mgbe ihe karịrị afọ iri nke nnyocha sayensị na ọhụrụ, ụlọ ọrụ amụtala ọnụ ọgụgụ nke onwe teknụzụ isi, nwere onwe R&D na imewe ike, na ike inye ahaziri mmepụta maka onye ọ bụla ahịa.