- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

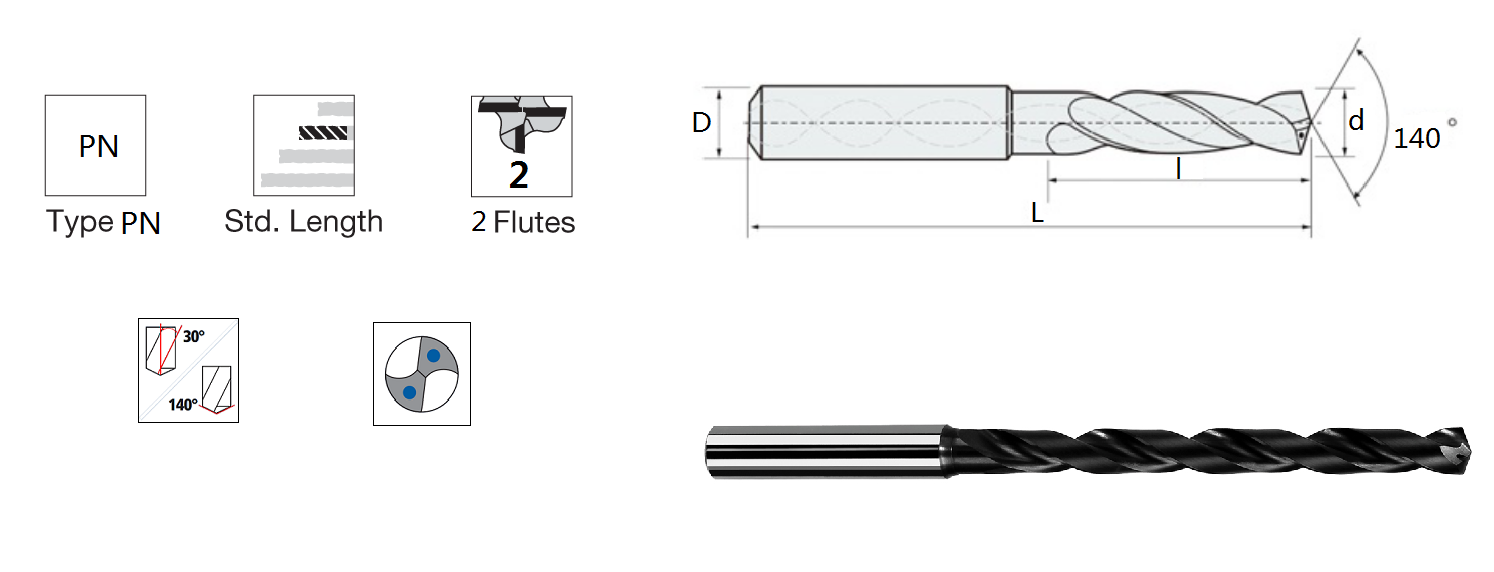

HJDK600 Inner Cooling Twist Drill pou rezon jeneral

Egzèsis tòde refwadisman enteryè pou rezon jeneral - 副本 - 副本

HJDK600 Inner Cooling Twist Drill pou rezon jeneral

Apwopriye pou perçage asye, asye pur, fè jete, materyèl ki pa fèr.

Nano Kouch AlTiN

Materyèl: tengstèn carbure

Deklarasyon literal:

HJDK600 Inner Cooling Twist Drill pou rezon jeneral

Egzèsis Carbide bay vitès koupe pi vit, lavi zouti ki pi long, pi bon presizyon pozisyon ak dimansyon ak amelyore fini sifas yo. Fant ak pòch fraisage souvan kreye pwoblèm evakyasyon chip, espesyalman sou sant machin vètikal. Re-koupe chips ka lakòz echèk moulen fen. Refwadisman-nan fen moulen ede evakye chips nan zòn nan koupe. Sa a elimine pwoblèm nan oswa re-koupe chips.

Karakteristik:

Apwopriye pou perçage asye, asye pur, fè jete, materyèl ki pa fèr.

Stub chisel, ekselan kapasite sant pwòp tèt ou.

Pwen radial, pi piti rezistans koupe.

Chanfrein lèv, pi wo pousantaj manje, pi wo efikasite.

Gwosè regilye:

| Kòd kòmande | Dyamèt deyò (D) | Longè fif (l) | Longè an jeneral (L) | Dyamèt tig (D) |

| HJDK600-0500D | 5.00 | 28 | 66 | 6 |

| HJDK600-0510D | 5.10 | 28 | 66 | 6 |

| HJDK600-0520D | 5.20 | 28 | 66 | 6 |

| HJDK600-0550D | 5.50 | 28 | 66 | 6 |

| HJDK600-0555D | 5.55 | 28 | 66 | 6 |

| HJDK600-0580D | 5.80 | 28 | 66 | 6 |

| HJDK600-0600D | 6.00 | 28 | 66 | 6 |

| HJDK600-0610D | 6.10 | 34 | 79 | 8 |

| HJDK600-0620D | 6.20 | 34 | 79 | 8 |

| HJDK600-0630D | 6.30 | 34 | 79 | 8 |

| HJDK600-0650D | 6.50 | 34 | 79 | 8 |

| HJDK600-0660D | 6.60 | 34 | 79 | 8 |

| HJDK600-0680D | 6.80 | 34 | 79 | 8 |

| HJDK600-0690D | 6.90 | 34 | 79 | 8 |

| HJDK600-0700D | 7.00 | 34 | 79 | 8 |

| HJDK600-0710D | 7.10 | 41 | 79 | 8 |

| HJDK600-0740D | 7.40 | 41 | 79 | 8 |

| HJDK600-0750D | 7.50 | 41 | 79 | 8 |

| HJDK600-0780D | 7.80 | 41 | 79 | 8 |

| HJDK600-0800D | 8.00 | 41 | 79 | 8 |

| HJDK600-0810D | 8.10 | 47 | 89 | 10 |

| HJDK600-0840D | 8.40 | 47 | 89 | 10 |

| HJDK600-0850D | 8.50 | 47 | 89 | 10 |

| HJDK600-0860D | 8.60 | 47 | 89 | 10 |

| HJDK600-0870D | 8.70 | 47 | 89 | 10 |

| HJDK600-0880D | 8.80 | 47 | 89 | 10 |

| HJDK600-0900D | 9.00 | 47 | 89 | 10 |

| HJDK600-0930D | 9.30 | 47 | 89 | 10 |

| HJDK600-0950D | 9.50 | 47 | 89 | 10 |

| HJDK600-0960D | 9.60 | 47 | 89 | 10 |

| HJDK600-0980D | 9.80 | 47 | 89 | 10 |

| HJDK600-1000D | 10.00 | 47 | 89 | 10 |

| HJDK600-1025D | 10.25 | 55 | 102 | 12 |

| HJDK600-1040D | 10.40 | 55 | 102 | 12 |

| HJDK600-1050D | 10.50 | 55 | 102 | 12 |

| HJDK600-1060D | 10.60 | 55 | 102 | 12 |

| HJDK600-1080D | 10.80 | 55 | 102 | 12 |

| HJDK600-1100D | 11.00 | 55 | 102 | 12 |

| HJDK600-1120D | 11.20 | 55 | 102 | 12 |

| HJDK600-1150D | 11.50 | 55 | 102 | 12 |

| HJDK600-1180D | 11.80 | 55 | 102 | 12 |

| HJDK600-1200D | 12.00 | 55 | 102 | 12 |

| HJDK600-1225D | 12.25 | 60 | 107 | 14 |

| HJDK600-1250D | 12.50 | 60 | 107 | 14 |

| HJDK600-1270D | 12.70 | 60 | 107 | 14 |

| HJDK600-1275D | 12.75 | 60 | 107 | 14 |

| HJDK600-1280D | 12.80 | 60 | 107 | 14 |

| HJDK600-1300D | 13.00 | 60 | 107 | 14 |

| HJDK600-1310D | 13.10 | 60 | 107 | 14 |

| HJDK600-1350D | 13.50 | 60 | 107 | 14 |

| HJDK600-1380D | 13.80 | 60 | 107 | 14 |

| HJDK600-1400D | 14.00 | 60 | 107 | 14 |

| HJDK600-1425D | 14.25 | 65 | 115 | 16 |

| HJDK600-1450D | 14.50 | 65 | 115 | 16 |

| HJDK600-1475D | 14.75 | 65 | 115 | 16 |

| HJDK600-1480D | 14.80 | 65 | 115 | 16 |

| HJDK600-1500D | 15.00 | 65 | 115 | 16 |

| HJDK600-1510D | 15.10 | 65 | 115 | 16 |

| HJDK600-1550D | 15.50 | 65 | 115 | 16 |

| HJDK600-1580D | 15.80 | 65 | 115 | 16 |

| HJDK600-1600D | 16.00 | 65 | 115 | 16 |

Nou ka pwodwi egzèsis 3D, 5D, 8D selon kondisyon kliyan anoswa egzèsis ki pa estanda kòm Customized.Nou ta ka tou pwodwi moulen fen ki pa estanda kòm Customized.

Konpozisyon materyèl zouti:

1. Pwopriyete fizik:

a. Dite ki pi gran pase oswa egal a 92.8 HRA;

b. Dansite ki pi gran pase oswa egal a 14.2g/cm³;

c. TRS ki pi gran pase oswa egal a 4200 N/mm²;

d. Gratis nan kondisyon faz ETA;

e. Pa gen kontaminasyon pa lòt materyèl;

f. Porosite = A00/B00/C00;

g. Gwosè grenn inifòm ak konsistan. Pa gen gwosè grenn ki ka pi gwo pase sa espesifye.

h. Kwòm carbure inibitè kwasans grenn sèlman.

2. Tout zouti pwodiksyon, kouch yo itilize nan Almay, Swis, pwosesis ekipman;

3. It's proposed cutting less than 60HRC.

Kouch:

Nano Kouch AlTiN

Karakteristik ak Fonksyon

1、High kontni aliminyòm bay ekselan dite cho ak rezistans oksidasyon.

2 、 metòd espesyal optimize estrikti kouch, estabilite siyifikativman amelyore, diminye kantite ti gout sifas yo.

Paramèt operasyon:

| Workpeice materyèl | Koupe | Pousantaj feed (mm/rev) | |||||||||

| vitès | |||||||||||

| (m/min) | |||||||||||

| Entèn | D3 | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D18 | D20 | |

| refwadisman | |||||||||||

| fè egzèsis | |||||||||||

| Asye ki ba kabòn, chip long | 14 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<125HB) | 100 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 60 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Asye ki ba kabòn, koupe kout, | 140 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| fasil koupe asye | 100 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<125HB) | 60 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Segondè asye kabòn ak mwayen | 120 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| kabòn asye | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| (<25HRC) | 60 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 |

| Asye alyaj, asye zouti | 110 | 0.09 | 0.11 | 0.14 | 0.19 | 0.23 | 0.24 | 0.28 | 0.3 | 0.33 | 0.34 |

| (<35HRC) | 80 | 0.13 | 0.15 | 0.19 | 0.25 | 0.3 | 0.33 | 0.38 | 0.42 | 0.42 | 0.43 |

| 50 | 0.16 | 0.19 | 0.23 | 0.31 | 0.38 | 0.41 | 0.45 | 0.5 | 0.5 | 0.51 | |

| Alloy steel,tool steel(35-48HRC) | 90 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| 60 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 | |

| 40 | 0.14 | 0.17 | 0.22 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 | |

| PH ak feritik, | 80 | 0.09 | 0.1 | 0.13 | 0.17 | 0.21 | 0.22 | 0.26 | 0.28 | 0.31 | 0.31 |

| asye martensitik | 50 | 0.12 | 0.14 | 0.17 | 0.23 | 0.28 | 0.3 | 0.35 | 0.37 | 0.38 | 0.39 |

| (<35HRC) | 30 | 0.14 | 0.17 | 0.23 | 0.29 | 0.35 | 0.37 | 0.41 | 0.44 | 0.46 | 0.47 |

| Austenitic asye pur | 50 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.11 | 0.12 | 0.13 | 0.14 |

| (130-200HB) | 40 | 0.08 | 0.1 | 0.12 | 0.13 | 0.15 | 0.17 | 0.18 | 0.2 | 0.22 | 0.24 |

| 20 | 0.1 | 0.12 | 0.14 | 0.18 | 0.2 | 0.22 | 0.24 | 0.24 | 0.26 | 0.28 | |

| Gwo fòs austenitic ak | 55 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 |

| fòje asye pur | 40 | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 |

| (<25HRC) | 30 | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 |

| Duplex en asye | 55 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | 0.1 | 0.12 |

| (<30HRC) | 40 | 0.06 | 0.08 | 0.08 | 0.1 | 0.11 | 0.13 | 0.13 | 0.14 | 0.14 | 0.16 |

| 20 | 0.08 | 0.1 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.18 | 0.2 | 0.22 | |

| Gri fè | 140 | 0.13 | 0.15 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 |

| (<32HRC) | 120 | 0.17 | 0.02 | 0.26 | 0.32 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | 0.48 |

| 60 | 0.21 | 0.26 | 0.32 | 0.4 | 0.42 | 0.46 | 0.5 | 0.52 | 0.54 | 0.56 | |

| Alyaj fè nan mwayen | 140 | 0.11 | 0.13 | 0.15 | 0.17 | 0.22 | 0.22 | 0.24 | 0.26 | 0.3 | 0.34 |

| Difikilte pou trete, | 120 | 0.15 | 0.18 | 0.23 | 0.26 | 0.28 | 0.34 | 0.35 | 0.4 | 0.4 | 0.43 |

| nodilè fè jete | 60 | 0.18 | 0.22 | 0.27 | 0.38 | 0.38 | 0.42 | 0.44 | 0.48 | 0.46 | 0.5 |

| (<28HRC) | |||||||||||

| Intractable segondè alyaj je jete, | 100 | 0.06 | 0.08 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.23 | 0.23 |

| nodilè fè jete | 90 | 0.09 | 0.1 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.28 | 0.29 |

| (<28HRC) | 60 | 0.11 | 0.13 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.34 | 0.35 |

| Fòje alyaj aliminyòm | 315 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (Si<12%) | 230 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

| Jete alyaj aliminyòm | 315 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (Si<12%) | 230 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

| Jete alyaj aliminyòm | 270 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (Si>12%) | 180 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

| Kwiv, alyaj kwiv | 180 | 0.06 | 0.13 | 0.16 | 0.18 | 0.2 | 0.22 | 0.24 | 0.28 | 0.32 | 0.34 |

| (<200HB) | 135 | 0.09 | 0.2 | 0.22 | 0.26 | 0.3 | 0.34 | 0.36 | 0.38 | 0.4 | 0.42 |

| 90 | 0.11 | 0.26 | 0.28 | 0.32 | 0.38 | 0.42 | 0.44 | 0.46 | 0.48 | 0.48 | |

Atansyon:

Asire w ke pyès travay ak machin yo estab epi sèvi ak yon detantè presizyon, sèvi ak mandrin idwolik, bon jan kalite mandrin kolye.

Asire w ke total ki endike kouri soti (TIR) se mwens pase 0.02mm.

Kondisyon koupe rekòmande a apwopriye pou aplike dlo idrosolubl.

Si gwosè zouti a pa nan tablo a. Tanpri gade nan klozèt tab la nan seleksyon an gwosè dyamèt lam nan paramèt koupe, ajiste paramèt koupe selon kondisyon aktyèl travay pandan pwosesis.

Konpayi an gen yon liy pwodiksyon ekipman pwosesis manifakti lam konplè soti nan preparasyon poud matyè premyè, fè mwazi, peze, presyon SINTERING, fanm k'ap pile, kouch ak kouch apre-tretman. Li konsantre sou rechèch la ak inovasyon nan materyèl la baz, estrikti Groove, fòme presizyon ak kouch sifas nan foure carbure NC, ak toujou ap amelyore efikasite nan machin, lavi sèvis ak lòt pwopriyete koupe nan foure carbure NC. Apre plis pase dis ane nan rechèch syantifik ak inovasyon, konpayi an te metrize yon kantite teknoloji debaz endepandan, gen endepandan R & D ak kapasite konsepsyon, epi li ka bay pwodiksyon Customized pou chak kliyan.