- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

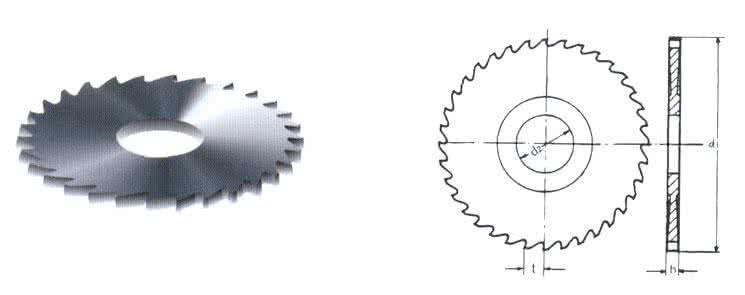

Tungsten carbide puag ncig txiav hniav

Carbide saw hniav cutter

Qhov Loj: 75 * 25.4 * T1.0-72T

Haum rau Hlau thiab ntoo Machining

Hardness: 92.6 HRA

tug :72t

Tungsten carbide puag ncig txiav hniav

Feem ntau ntawm cov saw cutters yog ua los ntawm tib hom kev kub ceev steel, carbide thiab lwm yam ntaub ntawv. Piv nrog rau kev kub ceev steel, cov carbide muaj hardness ntau dua, muaj zog txiav quab yuam, siab ceev thiab pub tus nqi, thiab ntau dua productivity.

Siv dav hauv: iav, watches, machinery, electronics, motors thiab lwm yam lag luam

Qhov zoo ntawm Tungsten carbide puag ncig txiav cov hniav, carbide pom cutters

1. Nrog submicron grain loj, zoo hnav-tiv taus, ntev kev pab cuam lub neej.

2. Nrog nruj kam rau ua raws li kev tswj hwm

3. Txaus siab rau zoo heev hnav tsis kam & siab toughnes

4. Cov txheej txheem tshwj xeeb Kub Isostatic Press (HIP) muab kev txhim kho zoo rau cov khoom tiav kom ntseeg tau cov khoom siv hluav taws xob

5. Peb ua tib zoo xaiv cov qib uas yuav tsum tau ua kom pom kev ua haujlwm zoo raws li kev paub ntau xyoo hauv kev ua haujlwm

| Sab nraud txoj kab uas hla (D) | Thickness (H) | Sab hauv txoj kab uas hla (d) | Teet (T) |

| 25 | 0.2--5.0 | 6 8 10 | 10--58 |

| 30 | 0.2--5.0 | 6 8 10 | 10--60 |

| 32 | 0.2--6.0 | 6 8 10 12.7 | 10--60 |

| 35 | 0.2--6.0 | 8 10 12.7 | 10--60 |

| 40 | 0.2--6.0 | 8 10 12.7 | 10--80 |

| 45 | 0.2--8.0 | 10 12.7 16 | 10--80 |

| 50 | 0.2--8.0 | 10 12.7 16 | 10--100 |

| 55 | 0.2--8.0 | 12.7 16 | 24--120 |

| 60 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 63 | 0.2--8.0 | 12.7 13 16 | 24--120 |

| 70 | 0.3--8.0 | 16 22 25.4 | 28--120 |

| 75 | 0.5--8.0 | 16 22 25 4 | 30--120 |

| 80 | 0.5--8.0 | 22 25.4 | 30--128 |

| 85 | 0.5--8.0 | 22 25.4 | 30--128 |

| 90 | 0.5--8.0 | 22 25.4 | 30--160 |

| 100 | 0.5--8.0 | 22 25.4 27 | 30--160 |

| 110 | 0.8--8.0 | 22 25.4 27 32 | 30--180 |

| 120 | 1.0--10.0 | 22 25.4 27 32 | 30-240 |

| 125 | 1.0--10.0 | 22 25.4 27 | 30-240 |

| 150 | 1.0--10.0 | 22 25.4 27 32 | 40-240 |

Cov khoom siv cuab yeej muaj pes tsawg leeg:

C) TRS ntau dua lossis sib npaug rau 3800 N / mm²;

Lub tuam txhab muaj kev ua tiav cov txheej txheem tsim cov khoom siv ntau lawm kab los ntawm cov hmoov raw khoom npaj, pwm ua, nias, siab sintering, sib tsoo, txheej thiab txheej tom qab kho. Nws tsom rau kev tshawb fawb thiab kev tsim kho tshiab ntawm cov khoom siv hauv paus, cov qauv zawj, kev sib sau ua tiav thiab txheej txheej ntawm carbide NC inserts, thiab niaj hnub txhim kho kev ua haujlwm zoo, kev pab cuam lub neej thiab lwm yam khoom txiav ntawm carbide NC inserts. Tom qab ntau tshaj kaum xyoo ntawm kev tshawb fawb thiab kev tsim kho tshiab, lub tuam txhab tau paub ntau yam ntawm cov thev naus laus zis ywj pheej, muaj kev ywj pheej R & D thiab tsim muaj peev xwm, thiab tuaj yeem muab cov khoom tsim kho rau txhua tus neeg siv khoom.