- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

Carbide rotary cuab tam rau metalworking

Carbide rotary cuab tam rau metalworking

Carbide rotary cuab tam rau metalworking

ib leeg txiav & ob-txiav

Khoom siv: Cemented carbide

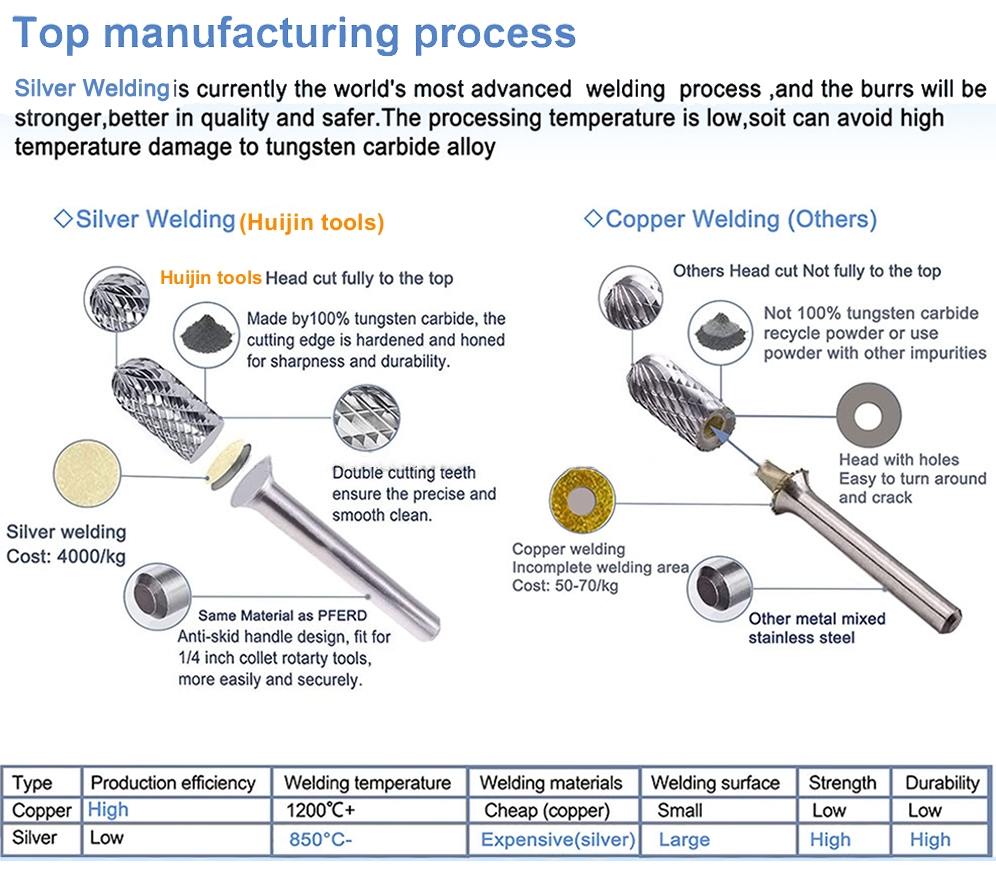

welding: nyiaj welding

Product Description

Cov ntaub ntawv carbide alloy rotary yog tus haum thiab pwm ua haujlwm qhov tseem ceeb tshaj plaws cov cuab yeej, nws cov yam ntxwv yog hloov rau txoj siv siv me me sib tsoo log thiab tsis muaj plua plav paug, kev pab cuam lub neej yog sib npaug rau ntau pua txoj siv me me sib tsoo log, kev ua haujlwm zoo. txhim kho saum toj no 5 zaug, hauv qab abrasive machning degree ntawm hardness HRC70 txhua cov hlau thiab cov hlau tsis yog hlau, sib tsoo nto roughness yuav ncav cuag Ral.6, yooj yim tuav, siv yooj yim, nyab xeeb txhim khu kev qha, txo cov arduous phau ntawv ua hauj lwm zoo heev, txo tus nqi ntawm ntau lawm.

Khoom siv: 100% raw khoom.

Kev kam rau siab: nruj kam rau ua raws li kev tswj hwm, uas tuaj yeem ncav cuag +/- 0.01mm;

Qib: ntau yam rau kev xaiv: YG6, YG8, YG8C, YG11C, YG15C thiab lwm yam.

Hom: txheem, conical, parabolic, ballistic

Lub cev ua haujlwm: siab hardness thiab cuam tshuam toughness, zoo heev mechanical & tshuaj stability.

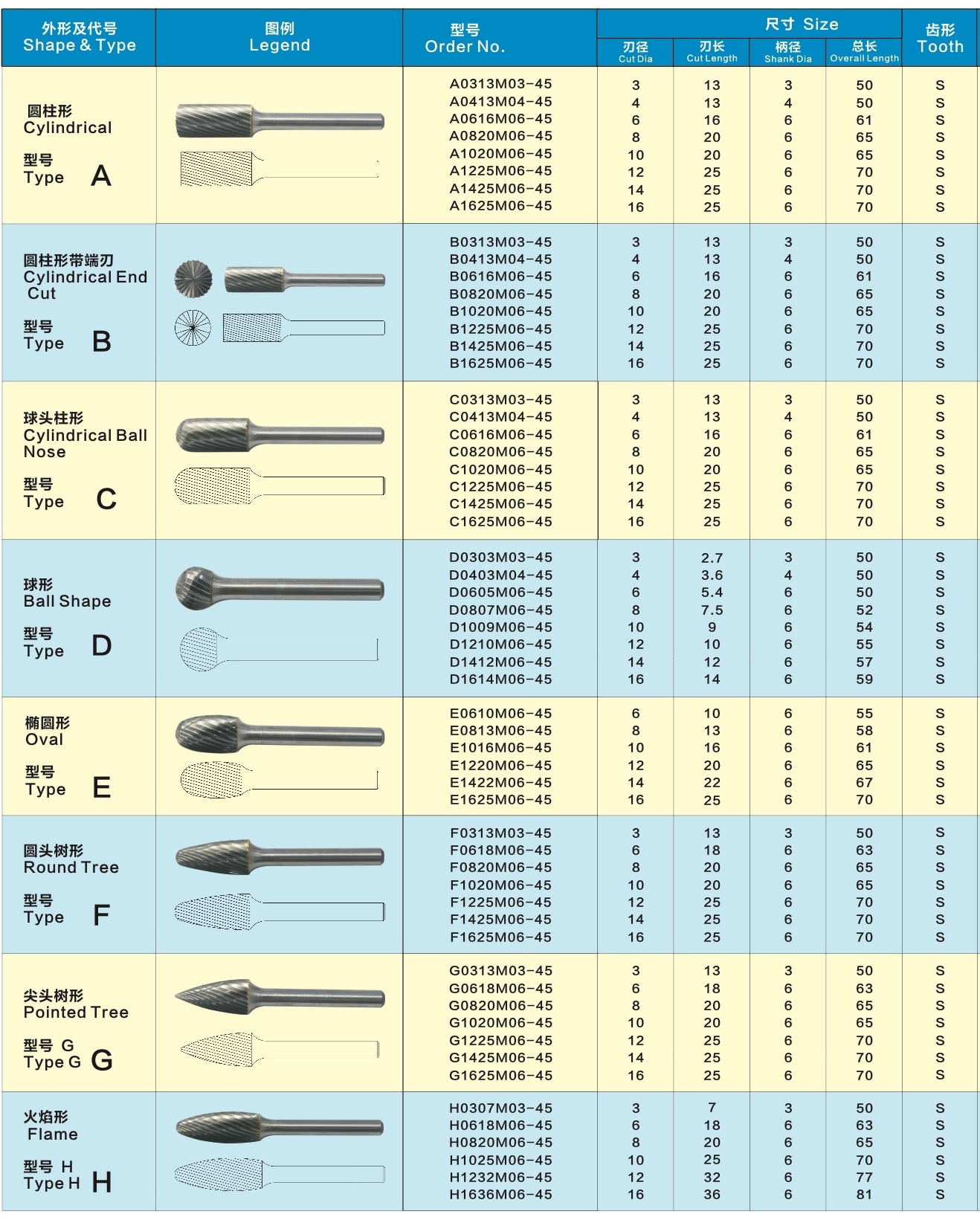

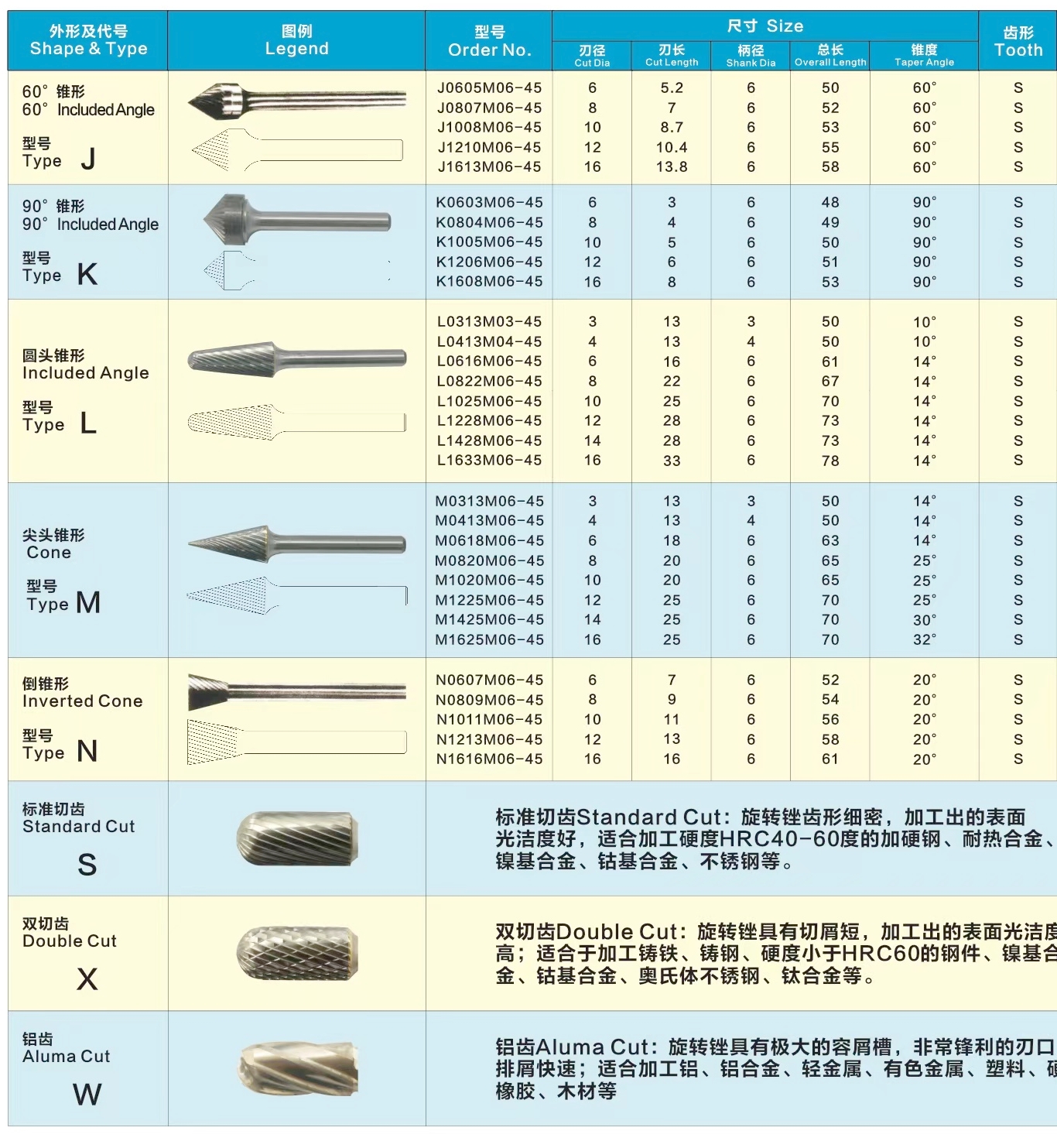

yam khoom/size

cov khoom duab

daim ntawv thov khoom

Cemented carbide rotary ntaub ntawv yog dav siv nyob rau hauv machinery, tsheb, nkoj, tshuaj lom neeg kev lag luam, khoom siv tes ua carving thiab lwm yam kev lag luam sectors, nrog zoo kawg li cov nyhuv. Nws lub ntsiab siv yog:

-- Zoo machining ntau yam hlau pwm kab noj hniav.-- Txhua yam hlau, uas tsis yog-hlau carving, thiab carving khoom plig.

--Thiab lub flash, burr thiab weld ntawm castings, forgings thiab weldments

--Chamfering, rounding thiab groove ua ntawm ntau yam khoom siv kho tshuab, tu cov kav dej, thiab ua tiav ntawm qhov chaw sab hauv ntawm cov khoom siv tshuab

-- Polishing ntawm impeller khiav.

Kev tswj kom zoo:

1.Tag nrho cov ntaub ntawv raw yog kuaj raws li qhov ceev, hardness thiab TRS ua ntej siv

2.Txhua yam khoom yuav dhau los ntawm kev ua haujlwm thiab kev tshuaj xyuas zaum kawg

3.Txhua batch ntawm cov khoom tuaj yeem taug qab

Cov txheej txheem tsim khoom thiab ua tiav ntawm cemented carbide

Hlau W\C hmoov:High purity tungsten hmoov yog siv los ua raw khoom.

Kev npaj sib tov:Lub pob zeb dov ua rau cov hmoov cov khoom xyaw homogenize.Qhov thaj tsam ntawm cov hmoov yog nce thiab cov particle nto yog nce.Can nce thiab txhawb sintering.

Slurry Drying:Kev npaj ntawm cov khoom sib tov yog siv nyob rau hauv ib puag ncig kaw.High purity nitrogen tiv thaiv, zoo txo qhov kev npaj.Nyob rau hauv cov txheej txheem, cov sib tov yuav ua rau kom oxygen, thiab can.Ua kom purity ntawm cov khoom thiab tiv thaiv cov khoom.Cov qias neeg.

Compression molding:Siv cov txheej txheem ntawm static siab mechanism, zoo du.Absolute suppression defects, siab ceev.and txawm.

Degumming thiab pre-burning semi-kev soj ntsuam ua

Nqus tsis tshua muaj siab sintering:Thermostatic sintering Qhov siab tshaj plaws sintering siab tuaj yeem ncav cuag 100 kg.Qhov seem seem tshem tawm hauv cov hlau yog qhov tsawg kawg nkaus.Ntxiv, nws yog compactand zoo.Degree, siab zog alloy dawb paug.Advanced tswj, qhov kub thiab txias system tuaj yeem txo qhov nyuaj alloy phaj. Qhov muaj peev xwm hloov tau zoo tshwm sim.

Semi-tiav kom qhuav, carbide blank khoom

Professional precision machining

Muaj ntau ntau hom machining txoj kev rau carbide precision machining. Xws li EDM, qeeb hlau txiav, CNC milling, CNC tshuab dhos ua, thiab lwm yam.

Peb lub compib qho yog cov chaw tsim khoom ntawm cemented carbide integrating ntau lawm thiab precision machining. Lub tuam txhab muaj ntau lawm thiab ua khoom siv xws li tig thiab milling compound machining chaw, tsib-axis machining chaw, plaub-axis ntsug machining chaw, CNC kab rov tav tho txawv thiab milling tshuab, sib sib zog nqus qhov drilling, tho txawv thiab honing, nqus sintering rauv, hlau txiav, thiab lwm yam. Kev txhawb nqa muaj peev xwm. Nws muaj zog heev nyob rau hauv precision machining ntawm cemented carbide, thiab yog txawm peem rau nrog ntau yam advanced machining khoom, uas yog haum rau lub machining ntawm ntau yam high-precision, tshwj xeeb cov ntaub ntawv, eccentric puab puab, luj tshib, thiab complex geometric qhov chaw.

Advanced tsom xam thiab kuaj cov cuab yeej

Huijin yog nruab nrog cov cuab yeej tshuaj ntsuam xyuas qib siab, xws li: carbon sulfur analyzer, TRS tester, metallographic microscope, coercivity tester, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop tester, micrometer, roundness tester, ultrasonic scanner, thiab lwm yam. ., txhua tus txheej txheem tuaj yeem soj ntsuam xyuas kom muaj txiaj ntsig zoo ntawm cov khoom.

Kev tshuaj xyuas cov khoom siv raw: siv lub tshuab ntsuas carbon-sulfur los txiav txim siab cov tshuaj muaj pes tsawg leeg ntawm tungsten carbide hmoov yog tsim nyog.

Tom qab sintering, siv cov cuab yeej los ntsuam xyuas cov khoom: kuaj TRS, microstructure, cobalt cov ntsiab lus, hardness ntawm cov khoom, cemented carbide pas nrig thiab tee test kom ntseeg tau tias tsis muaj qhov tsis xws luag hauv cov khoom, cemented carbide pwm dawb paug, ntxiv ultrasonic scanner kom tsis txhob xuab zeb Qhov hauv qhov khoob.

Kev tshuaj xyuas cov khoom siv tom qab sintering: Kev kuaj pom cov khoom tsis xws luag los ntawm cov neeg ua haujlwm txawj, suav nrog carburization thiab decarburization, nto xuab zeb qhov, me me tawg.

Dimensional check tom qab sintering: Xyuas qhov ntev nrog ib tug micrometer, thiab rau carbide rods, ntxiv roundness xeem.

Kev xa khoom / Packing

-Express tuam txhab uas muag: DHL, FedEx, TNT, UPS, thiab lwm yam.

-Airlines.

- Dej hiav txwv shipping

A. Txheem ntim

-Plastic thawv nrog ua npuas ncauj sab hauv thiab thawv sab nraud.

- Cov thawv ntawv nrog npuas sab hauv thiab thawv sab nraud.

-Cov thawv sab hauv / ntim khoom sab hauv thiab lub thawv plywood sab nraud (rau cov khoom hnyav)

Lub tuam txhab muaj kev ua tiav cov txheej txheem tsim cov khoom siv ntau lawm kab los ntawm cov hmoov raw khoom npaj, pwm ua, nias, siab sintering, sib tsoo, txheej thiab txheej tom qab kho. Nws tsom rau kev tshawb fawb thiab kev tsim kho tshiab ntawm cov khoom siv hauv paus, cov qauv zawj, kev sib sau ua tiav thiab txheej txheej ntawm carbide NC inserts, thiab niaj hnub txhim kho kev ua haujlwm zoo, kev pab cuam lub neej thiab lwm yam khoom txiav ntawm carbide NC inserts. Tom qab ntau tshaj kaum xyoo ntawm kev tshawb fawb thiab kev tsim kho tshiab, lub tuam txhab tau paub ntau yam ntawm cov thev naus laus zis ywj pheej, muaj kev ywj pheej R & D thiab tsim muaj peev xwm, thiab tuaj yeem muab cov khoom tsim kho rau txhua tus neeg siv khoom.