Kev txheeb xyuas ntawm cov cemented carbide inserts

Raws li nrog txhua tus neeg tsim cov khoom lag luam, kev tsim cov cam khwb cia hlau hnyav txiav hniav yuav tsum xub daws qhov teeb meem ntawm cov khoom siv raw, uas yog, txiav txim siab qhov sib xyaw thiab cov qauv ntawm cov ntaub ntawv hniav. Feem ntau ntawm cov hniav niaj hnub no yog ua los ntawm cov cemented carbide, uas yog tsim los ntawm tungsten carbide (WC) thiab cobalt (Co). WC yog ib qho nyuaj hauv cov hniav, thiab Co tuaj yeem siv los ua cov ntawv khi rau cov hniav.

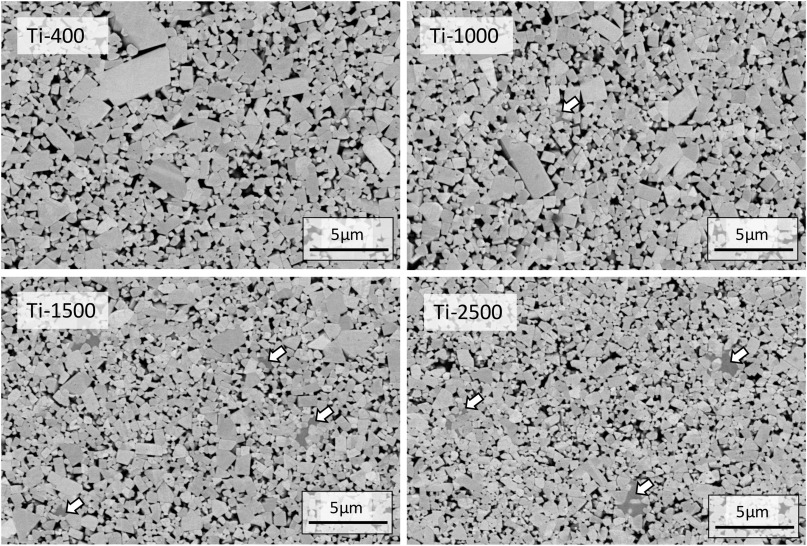

Ib txoj hauv kev yooj yim los hloov cov khoom ntawm cemented carbide yog hloov cov nplej loj ntawm WC hais siv. Qhov loj me me (3-5 μ m) Lub hardness ntawm cemented carbide khoom npaj los ntawm WC hais nrog C% yog tsawg thiab hnav yooj yim; Cov khoom me me (< 1 μ m) WC cov khoom tuaj yeem tsim cov khoom siv tawv tawv nrog cov tawv tawv dua, zoo dua hnav tsis kam, tab sis kuj muaj ntau dua brittleness. Thaum machining hlau cov ntaub ntawv uas muaj hardness heev, kev siv cov nplua nplej cemented carbide inserts yuav ua tau zoo kawg nkaus machining tau. Ntawm qhov tod tes, cov ntxhib nplej cemented carbide cov cuab yeej muaj kev ua tau zoo dua hauv kev txiav txiav lossis lwm yam machining uas yuav tsum tau muaj zog dua ntawm cov cuab yeej.

Lwm txoj hauv kev los tswj cov yam ntxwv ntawm cemented carbide inserts yog hloov qhov feem ntawm WC rau Co cov ntsiab lus. Piv nrog rau WC, lub hardness ntawm Co yog tsawg dua, tab sis lub toughness yog zoo dua. Yog li ntawd, txo cov ntsiab lus ntawm Co yuav ua rau cov hniav hardness ntau dua. Tau kawg, qhov no ib zaug ntxiv tsa qhov teeb meem ntawm kev sib npaug - ntau dua hardness hniav muaj kev hnav zoo dua, tab sis lawv cov brittleness kuj ntau dua. Raws li kev ua haujlwm tshwj xeeb, xaiv qhov tsim nyog WC grain loj thiab Co cov ntsiab lus piv yuav tsum muaj kev paub txog kev tshawb fawb thiab kev nplua nuj ua tiav.

Los ntawm kev siv cov khoom siv gradient, kev sib haum xeeb ntawm lub zog thiab lub zog ntawm cov hniav tuaj yeem zam tau qee qhov. Cov thev naus laus zis no, uas tau siv dav los ntawm lub ntiaj teb cov cuab yeej cuab tam loj, suav nrog kev siv cov ntsiab lus Co ntau dua nyob rau hauv txheej txheej ntawm cov hniav dua li hauv txheej txheej. Tshwj xeeb tshaj yog, txheej txheej ntawm cov hniav (thickness 15-25 μ m) Nce Co cov ntsiab lus los muab kev ua haujlwm zoo ib yam li "tsis muaj chaw", kom cov hniav tuaj yeem tiv taus qee yam tsis muaj kev tawg. Qhov no ua rau cov cuab yeej lub cev ntawm cov hniav kom tau txais ntau yam khoom zoo heev uas tuaj yeem ua tiav tsuas yog siv cov cemented carbide nrog lub zog siab dua.

Thaum cov particle loj, muaj pes tsawg leeg thiab lwm yam kev tsis ua hauj lwm ntawm raw cov ntaub ntawv raug txiav txim, qhov tseeb manufacturing txheej txheem ntawm txiav inserts yuav pib. Ua ntej, muab cov hmoov sib txuam tungsten, carbon hmoov thiab cobalt hmoov rau hauv ib lub zeb uas yog hais txog qhov loj tib yam li lub tshuab ntxhua khaub ncaws, zom cov hmoov rau qhov loj me me, thiab sib tov txhua yam khoom sib npaug. Thaum lub sij hawm milling txheej txheem, cawv thiab dej yog ntxiv los npaj ib tug tuab dub slurry. Tom qab ntawd cov slurry yog muab tso rau hauv lub tshuab ziab khaub ncaws, thiab cov kua hauv cov slurry yog evaporated kom tau cov hmoov lumpy thiab khaws cia.

Hauv cov txheej txheem kev npaj tom ntej, cov qauv ntawm cov hniav tuaj yeem tau txais. Ua ntej, cov hmoov npaj yog tov nrog polyethylene glycol (PEG). Raws li cov yas yas, PEG tuaj yeem txuas cov hmoov ua ke ib ntus zoo li khob noom cookie. Cov khoom yog ces nias rau hauv cov duab ntawm ib tug hniav nyob rau hauv ib tug tuag. Raws li kev sib txawv ntawm cov hniav nias, ib qho axis xovxwm tuaj yeem siv rau kev nias, lossis ntau axis xovxwm tuaj yeem siv los nias cov hniav los ntawm ntau lub kaum sab xis.

Tom qab tau txais cov xovxwm dawb, nws muab tso rau hauv lub qhov cub loj sintering thiab sintered ntawm qhov kub thiab txias. Nyob rau hauv cov txheej txheem sintering, PEG yog melted thiab tawm los ntawm cov billet sib tov, tawm hauv ib tug semi-tiav cemented carbide hniav. Thaum PEG melts tawm, cov hniav shrinks rau nws * zaum kawg loj. Cov kauj ruam ntawm cov txheej txheem no yuav tsum muaj kev suav lej kom raug, vim tias qhov shrinkage ntawm cov hniav sib txawv raws li cov khoom sib txawv thiab qhov sib piv, thiab qhov ntev ntev ntawm cov khoom tiav yuav tsum tau tswj nyob rau hauv ntau microns.

Sijhawm Sijhawm: 2023-01-15