- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

HJDK650 Tungsten carbide kikowaena kikowaena

ʻO nā hoʻoheheʻe kikowaena tungsten carbide

HJDK650 Tungsten carbide kikowaena kikowaena

He kūpono no ka hoʻoheheʻe ʻana i ke kila, ke kila kila, ka hao hoʻolei, nā mea hao ʻole.

Oolea HRA92.8

Mea: tungsten carbide

HJDK650 series-center drills

ʻŌlelo maoli:

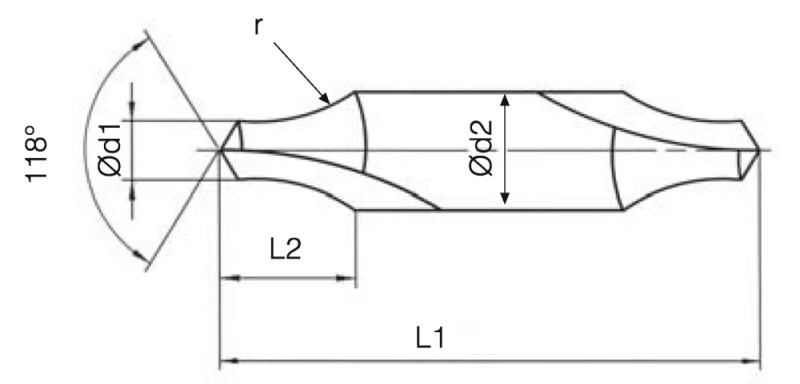

ʻIke ʻo HJDK650 kikowaena waena i kahi hui maikaʻi ma waena o ke kahe ʻana o ka puʻupuʻu ma ka ʻāpana drill a me kēlā ma ka ʻāpana countersink. Hiki i kā lākou mau ʻōheʻe ke hoʻokomo pono i nā chips a hana maikaʻi no ka hoʻokuʻu ʻana i nā chips. ʻO nā drills kikowaena ka ʻoki ʻana i nā kihi ma nā ʻaoʻao ʻelua, a he spiral flutes. ikaika, ua hōʻemi mākou i ka lōʻihi drill. No ka hoʻopaʻi hou ʻana i ka nāwaliwali ma ke kiko hoʻohui ma waena o ka drill a me ka countersink, aia ka wahi hoʻohui i R ʻo ia ka radius i loko o ke kua o ka drill. Loaʻa iā lākou kahi laina ākea.

Nā hiʻohiʻona:

He kūpono no ka hoʻoheheʻe ʻana i ke kila, ke kila kila, ka hao hoʻolei, ka mea hao ʻole.

Stub chisel, hiki ke kikowaena pono'ī.

Lae radial, ʻokiʻoki liʻiliʻi.

Lip chamfer, ʻoi aku ka nui o ka hānai, ʻoi aku ka maikaʻi.

Nui mau:HJʻO DK650 Nā Paʻa Paʻa Paʻa Māmā

| Helu kauoha | Anawaena | Angle | Ka lōʻihi o ka ʻohe | O.A.L. | Shank Dia. |

| HJDK650-0102 | 1 | 60° | 1.5 | 35 | 4 |

| HJDK650-0202 | 2 | 60° | 2.5 | 50 | 5 |

| HJDK650-0252 | 2.5 | 60° | 3 1 | 60 | 6.3 |

| HJDK650-03152 | 3.15 | 60° | 3.9 | 70 | 8 |

| HJDK650-0402 | 4 | 60° | 5 | 80 | 10 |

| HJDK650-0502 | 5 | 60° | 6.3 | 80 | 12 |

| HJDK650-0632 | 6.3 | 60° | 80 | 80 | 16 |

Mea hana mea hana haku:

1. Nā Pono Kino:

A) ʻoi aku ka paʻakikī ma mua o a i ʻole like me 92.8 HRA;

B) ʻOi aku ka nui ma mua a i ʻole like me 14.2 g/cm³;

C) ʻoi aku ka nui o TRS ma mua a i ʻole like me 4200 N/mm²;

D) ʻAʻohe kūlana ETA phase;

E) ʻAʻohe haumia e nā mea ʻē aʻe;

F) Porosity = A00 / B00 / C00 ;

G) Kaulike ka nui o ka palaoa. ʻAʻole hiki ke ʻoi aku ka nui o ka palaoa ma mua o ka mea i ʻōlelo ʻia.

H) ʻO Chromium carbide ka mea hoʻoulu ulu wale nō.

2. Hoʻohana ʻia nā mea hana a pau, nā uhi i Kelemānia, Switzerland, mea hana;

Ka palena hana:

| Nā ʻāpana hana wili waena: | ||||||||||

| Mea hana mea hana | ʻOki wikiwiki | Laki ʻai (mm/rev) | ||||||||

| (m/min) | D4 | D6 | D8 | D10 | D12 | D14 | D16 | D20 | ||

| Low carbon steel, long chip (<125HB) | 130 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.15 | 0.17 | 0.2 | 0.24 | 0.26 | 0.3 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.26 | 0.3 | 0.32 | 0.35 | 0.4 | 0.45 | ||

| hao haʻahaʻa, ʻoki pōkole, hao maʻalahi ( | 120 | 0.1 | 0.14 | 0.16 | 0.18 | 0.2 | 0.24 | 0.28 | 0.32 | |

| 100 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.34 | 0.38 | ||

| 60 | 0.18 | 0.2 | 0.24 | 0.3 | 0.32 | 0.34 | 0.4 | 0.45 | ||

| hao kalapona kiʻekiʻe a me hao kalapona waena ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Aila huila, kila mea paahana ( | 110 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Aila huila, kila mea paahana (35-48HRC) | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| PH a ferritic, martensitic steels ( | 100 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 80 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| Gray iron(<32HRC) | 140 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| ʻO ka hao huikau o ka paʻakikī o ka hoʻoponopono ʻana, ka hao nodular ( | 130 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 105 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Ka hao hao kiʻekiʻe hiki ke hoʻopili ʻia, hao nodular ( | 120 | 0.1 | 0.1 | 0.13 | 0.15 | 0.17 | 0.19 | 0.2 | 0.28 | |

| 90 | 0.16 | 0.13 | 0.17 | 0.2 | 0.22 | 0.26 | 0.27 | 0.29 | ||

| 60 | 0.22 | 0.16 | 0.21 | 0.26 | 0.28 | 0.31 | 0.33 | 0.35 | ||

| Aluminum alloy (Si | 150 | 0.12 | 0.17 | 0.2 | 0.25 | 0.26 | 0.28 | 0.3 | 0.32 | |

| 120 | 0.2 | 0.26 | 0.32 | 0.3 | 0.32 | 0.32 | 0.36 | 0.38 | ||

| 60 | 0.26 | 0.32 | 0.4 | 0.36 | 0.38 | 0.4 | 0.42 | 0.44 | ||

| Hoʻolei aluminium alloy (Si | 150 | 0.12 | 0.15 | 0.17 | 0.2 | 0.22 | 0.24 | 0.26 | 0.3 | |

| 120 | 0.18 | 0.2 | 0.22 | 0.26 | 0.28 | 0.3 | 0.32 | 0.36 | ||

| 60 | 0.24 | 0.27 | 0.3 | 0.32 | 0.34 | 0.36 | 0.38 | 0.42 | ||

| Hoʻolei aluminium alloy (Si>12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.13 | 0.15 | 0.18 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.22 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

| 12%) | 150 | 0.1 | 0.12 | 0.14 | 0.16 | 0.18 | 0.2 | 0.22 | 0.26 | |

| 120 | 0.12 | 0.14 | 0.16 | 0.2 | 0.24 | 0.26 | 0.28 | 0.32 | ||

| 60 | 0.16 | 0.18 | 0.2 | 0.24 | 0.3 | 0.3 | 0.32 | 0.4 | ||

Ke keleawe, mea hui keleawe (

Nānā:

E hōʻoia i ka paʻa o ka ʻāpana hana a me ka mīkini a hoʻohana i kahi paʻa pololei, hoʻohana i nā pahu hydraulic, nā kiʻi collet kiʻekiʻe.

E hōʻoia i ka huina holo-waho (TIR) i hōʻike ʻia ma lalo o 0.02mm.

ʻO ke kūlana ʻoki i ʻōlelo ʻia he kūpono ia no ka hoʻohana ʻana i ka wai hiki ke hoʻoheheʻe ʻia.

Loaʻa i ka hui kahi laina hana hana ʻenehana piha mai ka pauka maka mea hoʻomākaukau, hana ʻia, kaomi ʻana, kaomi sintering, wili, ka uhi a me ka uhi ʻana ma hope o ka mālama ʻana. Hoʻopili ia i ka noiʻi a me ka hana hou o ka waihona kumu, ka hoʻolālā groove, ka hoʻokumu pololei ʻana a me ka uhi ʻana o ka carbide NC inserts, a hoʻomaikaʻi mau i ka hana machining, ke ola lawelawe a me nā waiwai ʻoki ʻē aʻe o ka carbide NC inserts. Ma hope o ʻumi mau makahiki o ka noiʻi ʻepekema a me ka hana hou, ua ʻike ka hui i nā ʻenehana kumu kūʻokoʻa, loaʻa iā R&D kūʻokoʻa a me nā mana hoʻolālā, a hiki ke hāʻawi i ka hana maʻamau no kēlā me kēia mea kūʻai.