- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

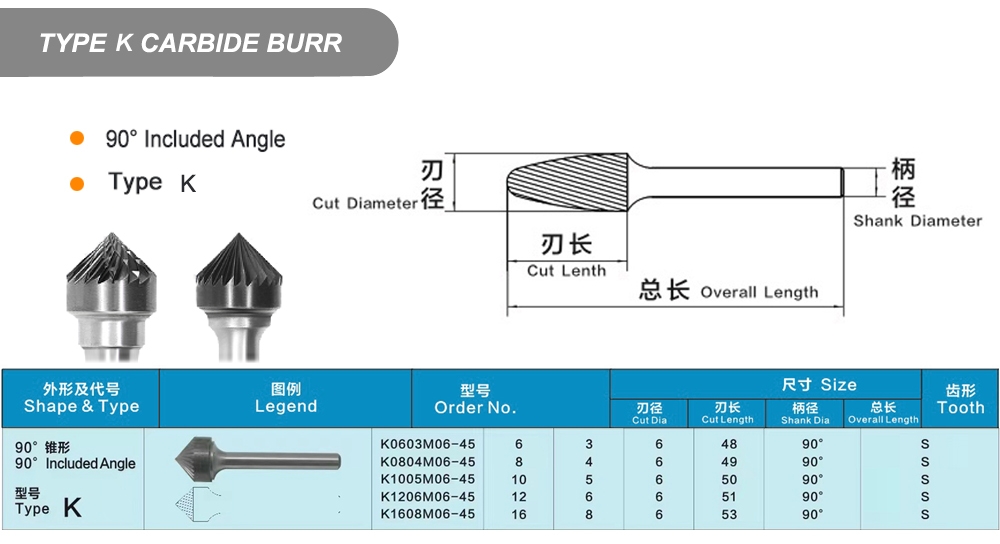

K type Carbide Rotary Burr

K type rotary files

K type Carbide Rotary Burr

ʻoki hoʻokahi & ʻoki ʻelua

Maikaʻi: carbide sima

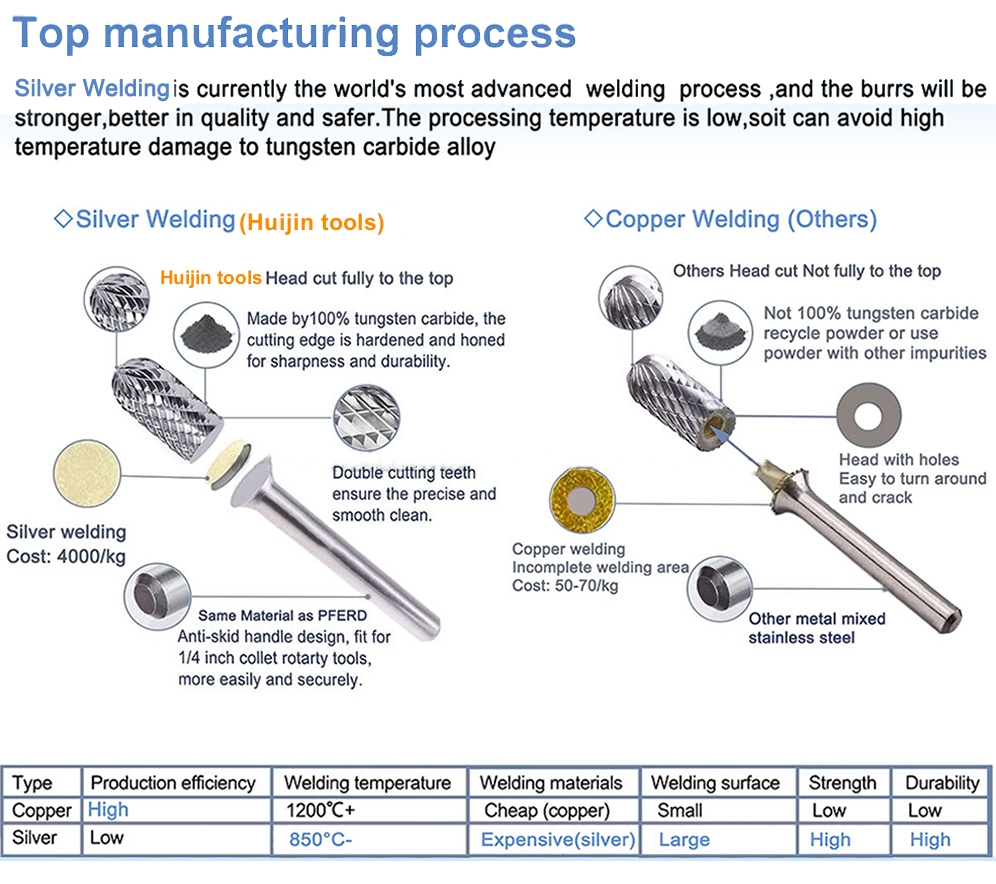

wiliwili: silver welding

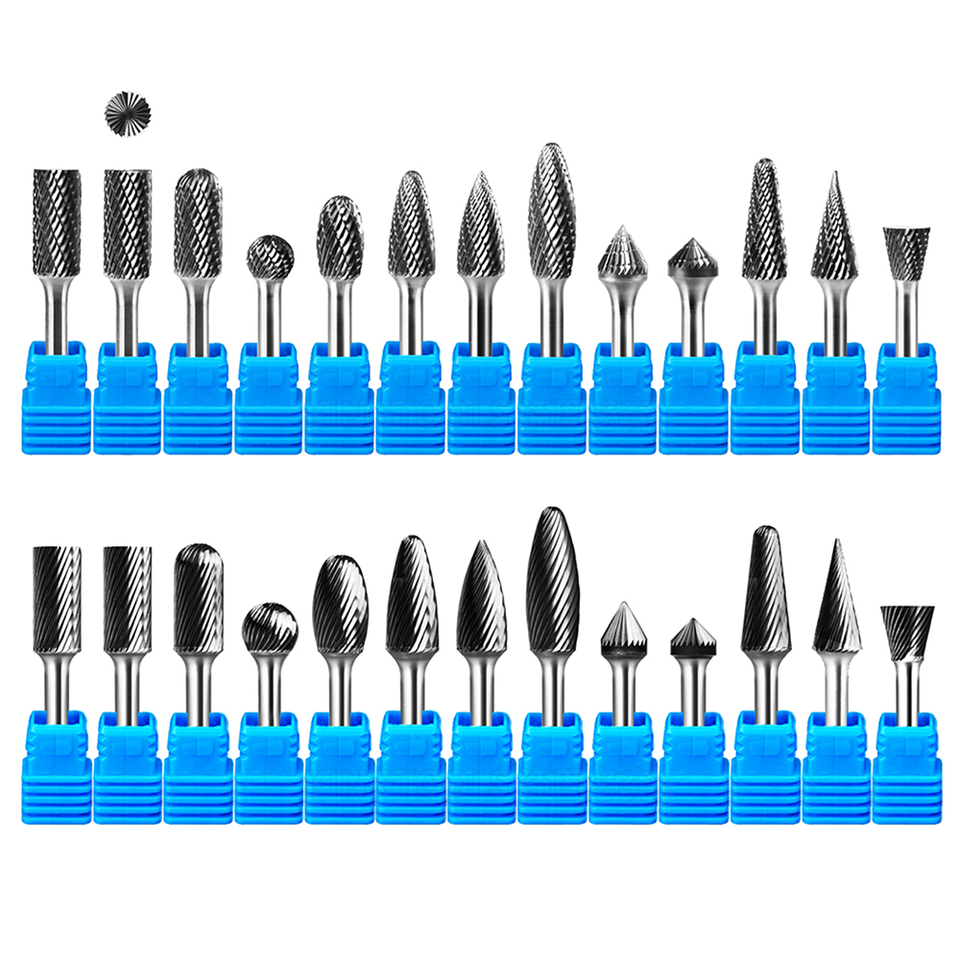

Hōʻike huahana

ʻO ka carbide alloy rotary file ʻo ia ka mea pono a me ka mold labor's indispensable advanced tool, kona hiʻohiʻona he pani no ke kāʻei kāʻei liʻiliʻi wili huila a me ka haumia ʻole o ka lepo, ua like ke ola lawelawe me nā haneli he nui o ke kāʻei lima liʻiliʻi wili liʻiliʻi, ka hana effciency. hoʻonui ma luna o 5 manawa, ma lalo abrasive machning degere o ka paakiki HRC70 kēlā me kēia metala a me ka nonmetallic meterial, wili ili roughness hiki ke hiki i Ral.6, oluolu grasps, hoʻohana i ka maʻalahi, palekana hilinaʻi, ho'ēmi i ka arduous lima hana nui, hoemi i ke kumukuai o hana ʻana.

Material: 100% o nā mea maka.

ʻO ka hoʻomanawanui: ka mana hoʻomanawanui koʻikoʻi, hiki ke hiki i +/-0.01mm;

Papa: ʻokoʻa no ke koho: YG6, YG8, YG8C, YG11C, YG15C a pēlā aku.

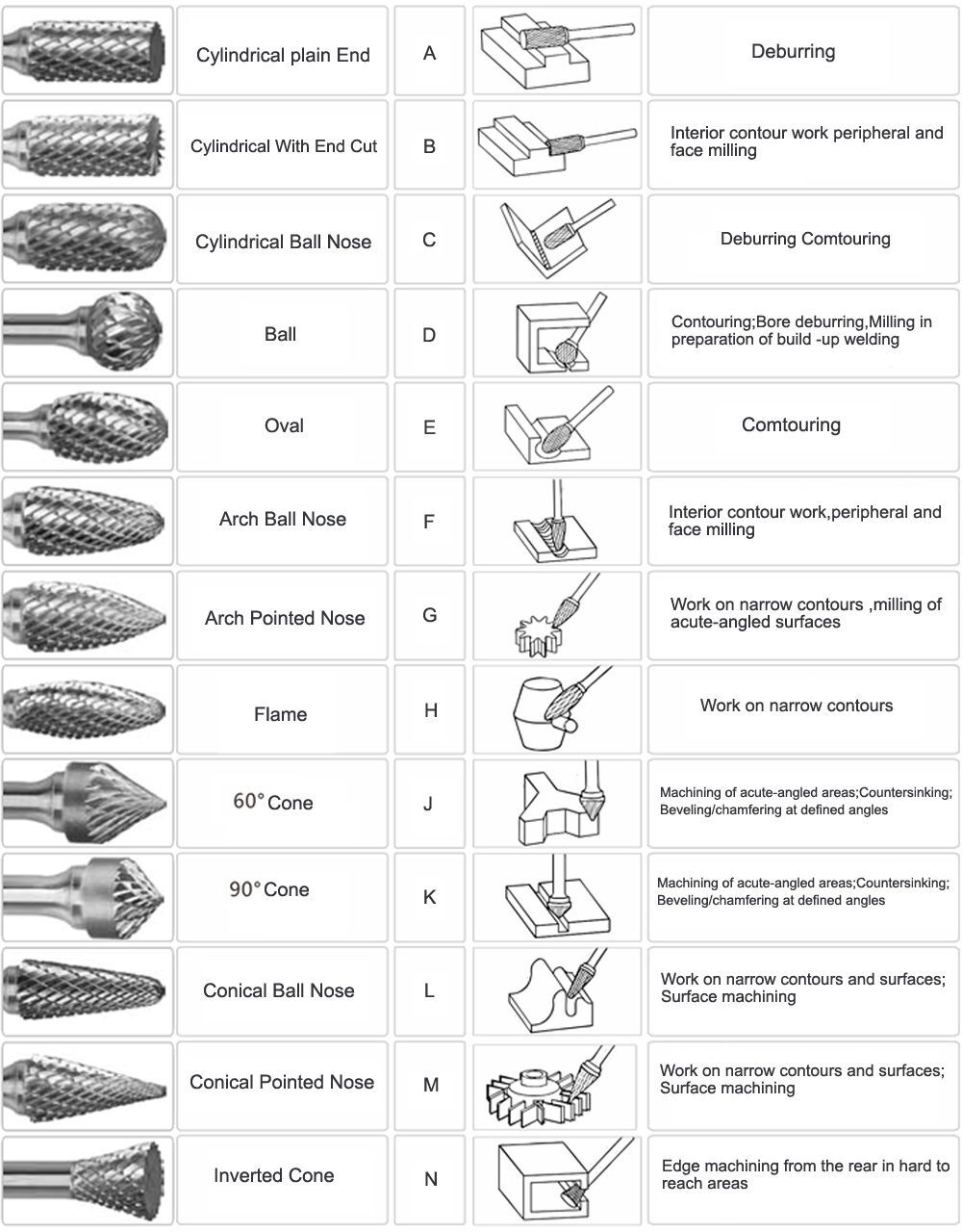

Nā ʻano: maʻamau, conical, parabolic, ballistic

ʻO ka hana kino: ʻoi aku ka paʻakikī a me ka paʻakikī o ka hopena, maikaʻi loa ka mechanical & kemika paʻa.

ʻano huahana/nui

noi huahana

Hoʻohana nui ʻia ka faila carbide rotary cemented i nā mīkini, kaʻa, moku, ʻoihana kemika, kālai kiʻi a me nā ʻoihana ʻoihana ʻē aʻe, me ka hopena kupaianaha. ʻO kāna mau hoʻohana nui:

-- Mīkini maikaʻi ʻia nā lua poni metala.-- ʻO nā ʻano metala a pau, kalai ʻole metala, a me ke kālai ʻana i nā makana hana.

--E hoʻomaʻemaʻe i ka uila, burr a me ka weld o nā hoʻoheheʻe, forgings a me nā weldments

--Chamfering, hoʻopuni a me ka hana ʻana o nā ʻāpana mechanical like ʻole, hoʻomaʻemaʻe i nā paipu, a me ka hoʻopau ʻana i nā ʻili o loko o nā ʻāpana mechanical

-- Ka hoolei ana i ke kukini impeller.

Mana maikaʻi:

1. Hoʻāʻo ʻia nā mea maka a pau ma ke ʻano o ka density, paʻakikī a me TRS ma mua o ka hoʻohana ʻana

2. Ke hele nei kēlā me kēia ʻāpana o ka huahana i ka hana a me ka nānā hope

3. Hiki ke ʻike ʻia kēlā me kēia pūʻulu huahana

Kaʻina hana a me ka hoʻopau ʻana i ka carbide cemented

Metala W\C Pauka:Hoʻohana ʻia ka pauka tungsten maʻemaʻe kiʻekiʻe e like me ka mea maka.

Hui hoʻomākaukau:ʻO ka wili pōleʻa ʻōwili e hana i nā mea pauka homogenize. Hoʻonui ʻia ka ʻili o ka pauka a hoʻonui ʻia ka ʻili o ka ʻāpana. Hiki ke hoʻonui a hoʻoikaika i ka sintering.

Slurry spray dryingHoʻohana ʻia ka hoʻomākaukau ʻana o ka hui ʻana i loko o kahi ʻano paʻa.

Hoʻopili ʻia:Ke hoʻohana nei i ke ʻano o ka mīkini paʻi paʻa, ʻoi aku ka maikaʻi o ka du.Absolute suppression of defects, high density.and even.

Degumming a me ka hana semi-inspection pre-burning

Vacuum haʻahaʻa kaomi sintering:thermostatic sintering Hiki ke hiki i ka 100 kg ka nui o ka hole hole i loko o ka huila. Hiki ke loli ka maikaʻi.

ʻO ka hoʻomaloʻo semi-hoʻopau, nā huahana carbide blank

ʻOihana mikini pololei

Nui nā ʻano hana mīkini no ka mīkini pololei carbide. E like me EDM, ʻoki uea lohi, CNC milling, CNC lathe processing, etc.

ʻO kā mākou compʻO kekahi mea hana loea o ka carbide cemented e hoʻohui i ka hana a me ka mīkini pololei. Ua holomua ka hui i ka hana a me ka hana ʻana i nā mea hana e like me ka huli ʻana a me ka milling compound machining center, five-axis machining center, ʻehā-axis vertical machining center, CNC horizontal boring and milling machine, hohonu lua drilling, boring and honing, vacuum sintering furnace, wire ʻokiʻoki, a pēlā aku. Loaʻa ka ikaika ikaika loa i ka mīkini pololei o ka carbide cemented, a ua hoʻolako ʻia me nā mea hana mīkini holomua, kūpono no ka hana ʻana i nā ʻano kiʻekiʻe kiʻekiʻe, nā mea kūikawā, eccentric i loko, nā kuʻekuʻe, a me nā ʻāpana geometric paʻakikī.

ʻO ka loiloi kiʻekiʻe a me nā lako hoʻāʻo

Hoʻolako ʻia ʻo Huijin me ka hoʻomaʻamaʻa ʻana a me nā lako hoʻāʻo, e like me: carbon sulfur analyzer, TRS tester, metallographic microscope, coercivity tester, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop tester, micrometer, roundness tester, ultrasonic scanner, etc. ., Hiki ke nānā pono i kēlā me kēia kaʻina hana e hōʻoia i ka helu kūpono o nā huahana.

Ka nānā 'ana i nā mea maka: e ho'ohana i ka mea ho'oponopono kalapona-sulfur e ho'oholo ai i ka hana kemika o ka pauka tungsten carbide.

Ma hope o ka sintering, e hoʻohana i ka mea kani e hoʻāʻo ai i ka mea: e hoʻāʻo i ka TRS, microstructure, cobalt content, hardness o ka mea, cemented carbide rod a drop test e hōʻoia ʻaʻohe hemahema waena i loko o ka mea, cemented carbide mold blank, hoʻohui ultrasonic ʻo ka scanner e pale i ke one Hole i loko o ka hakahaka.

Nānā mea lima ma hope o ka hoʻopaʻa ʻana: Nānā ʻike ʻia o nā hemahema waiwai e nā limahana akamai, me ka carburization a me ka decarburization, nā lua one ma luna, nā māwae liʻiliʻi.

Nānā ana ma hope o ka sintering: E nānā i nā ana me ka micrometer, a no nā lāʻau carbide, e hoʻohui i ka hoʻāʻo pōʻai.

ʻO nā ala hāʻawi / Packaging

-Express hui: DHL, FedEx, TNT, UPS, etc.

-Nā mokulele.

-Ka moku moana

A. Hoʻopili maʻamau

-ʻO nā pahu plastik me ka huʻa i loko a me ka pahu pahu ma waho.

- Nā pahu pepa me ka huʻa i loko a me ka pahu pahu ma waho.

-ʻO nā pahu i loko / ʻeke mea i loko a me ka pahu plywood ma waho (no ka huahana kaumaha)

Loaʻa i ka hui kahi laina hana hana ʻenehana piha mai ka pauka maka mea hoʻomākaukau, hana ʻia, kaomi ʻana, kaomi sintering, wili, ka uhi a me ka uhi ʻana ma hope o ka mālama ʻana. Hoʻopili ia i ka noiʻi a me ka hana hou o ka waihona kumu, ka hoʻolālā groove, ka hoʻokumu pololei ʻana a me ka uhi ʻana o ka carbide NC inserts, a hoʻomaikaʻi mau i ka hana machining, ke ola lawelawe a me nā waiwai ʻoki ʻē aʻe o ka carbide NC inserts. Ma hope o ʻumi mau makahiki o ka noiʻi ʻepekema a me ka hana hou, ua ʻike ka hui i nā ʻenehana kumu kūʻokoʻa, loaʻa iā R&D kūʻokoʻa a me nā mana hoʻolālā, a hiki ke hāʻawi i ka hana maʻamau no kēlā me kēia mea kūʻai.