He aha ka Carbide Rotary File? Pehea e hoʻoponopono ai i nā pilikia i ka hoʻohana ʻana i nā faila rotary carbide?

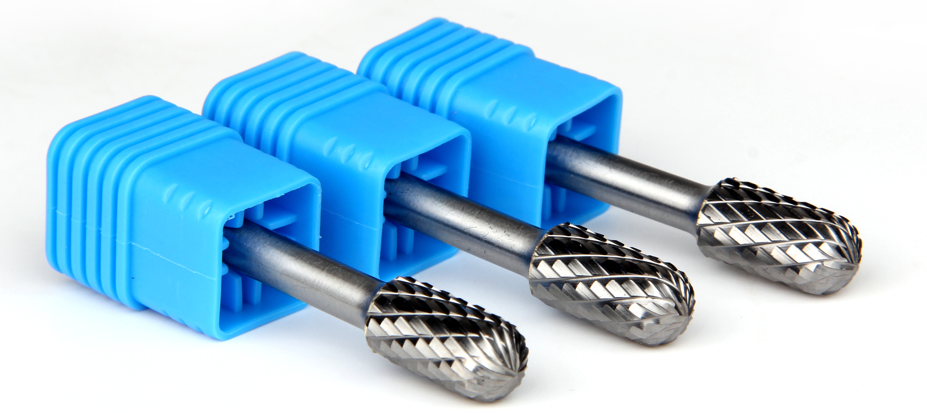

Carbide Rotary Burrs

Carbide rotary files, also known as carbide high-speed assorted milling cutters, carbide mold milling cutters, etc., ua alakaʻi nui ʻia e nā mea uila a i ʻole nā mea pneumatic (a hiki ke hoʻokomo ʻia ma nā mea mīkini kiʻekiʻe).

Hoʻolauna

Nui kona hoʻohana ʻana, ʻoi aku hoʻi i ka mokulele, nā moku, nā kaʻa, nā mīkini, nā kemika a me nā ʻoihana ʻoihana ʻē aʻe. Hiki ke hoʻohana ʻia e hana i ka hao, ke kila kila, ke kila kalapona, ke kila kila, ke kila kila, ke kila paʻakikī, ke keleawe a me ka aluminika, a pēlā aku. Hoʻoholo ʻia ka wikiwiki hānai o ka faila rotary e ke ola lawelawe a me ka hopena ʻoki o ka mea hana

ʻO ka pōmaikaʻi o ka huijin carbidenā faila rotary

1. Hiki iā ia ke hana i nā metala e like me ka hao, ke kila kila, ke kila kalapona, ke kila kila, ke kila kila, ke keleawe, ka aluminika, a me nā metala ʻole e like me ke kinikini, ka jade, a me ka iwi.

2. ʻO ke kumu, hiki iā ia ke pani i ka huila wili liʻiliʻi me ka lima, ʻaʻohe lepo lepo.

3. Hoʻoikaika kiʻekiʻe. ʻOi aku ka maikaʻi o ka hana ʻana ma mua o nā faila manual, a kokoke i ʻumi mau manawa kiʻekiʻe ma mua o nā huila wili liʻiliʻi me nā lima.

4. ʻO ka maikaʻi hana maikaʻi a me ka hoʻopau kiʻekiʻe. Hiki iā ia ke hana i nā ʻokoʻa kiʻekiʻe kiʻekiʻe.

5. Ke ola lōʻihi. ʻO ka lōʻihi heʻumi manawa kiʻekiʻe ma mua o nā mea hana kila kiʻekiʻe, aʻoi aku ma mua o 200 manawa kiʻekiʻe ma mua o nā huila wili liʻiliʻi.

6. Maʻalahi e hoʻohana, palekana a hilinaʻi.

7. He kiʻekiʻe ka maikaʻi o ka hoʻohana ʻana, a hiki ke hoʻemi ʻia ke kumukūʻai hoʻoponopono piha e nā manawa he nui.

I ka hoʻohana ʻana i nā carbide burrs, pono e hahai ʻia nā pae aʻe:

1. E koho i ka faila rotary kūpono, a me ka wikiwiki kūpono a me ke kaomi e like me ka mea a me ka paʻakikī o ka mea hana e hana ʻia.

2. E hoʻopaʻa i ka faila rotary ma ka mea uila a i ʻole ka mea hana ea, hoʻopili a hōʻoia i ka pololei o ka paʻi.

3. E hoʻopaʻa i ka mea hana ma ka papaʻaina a e hōʻoia i ka paʻa o ka pipili.

4. I ka hoʻomaka ʻana i ka hana rotary, pono e mālama i ke kuhikuhi ʻoki ʻana mai ka ʻākau a i ka hema, e pale i ka hoʻohana ʻana i ka faila rotary i hoʻopaʻa ʻia i ke awāwa a i ʻole ke āpau, a mai hoʻohana i ka faila rotary e wili a wili paha i ka mea hana.

5. E hoʻolohe i ka palekana i ka wā e hoʻohana ai, a e hoʻokomo i nā aniani pale kūpono e pale ai i ka faila rotary mai ka lele ʻana a hōʻeha i nā kānaka.

6. Ma hope o ka hana ʻana, e wehe i ka faila rotary mai ka mea uila a i ʻole ka mea hana ea, hoʻomaʻemaʻe a mālama.

Pono e hoʻomaopopo ʻia he kiʻekiʻe ka paʻakikī o ka faila rotary carbide a me ke kūpaʻa ʻana, akā he palupalu a maʻalahi hoʻi e haki a haki paha. No laila, pono ka mālama kūikawā i ka wā o ka hoʻohana ʻana i mea e pale ai i ka haʻalulu a i ʻole ke kaumaha nui. I ka manawa like, pono e hoʻomalu i ka wikiwiki a me ke kaomi i ka wā o ka hana e pale i ka vibration a me ka wela.

Loaʻa pinepine nā faile rotary Carbide i kēia mau pilikia i ka wā e hoʻohana ai:

1. ʻAʻole kiʻekiʻe ka pololei o ka hana ʻana: ʻo ka pololei o ka hana ʻana o ka faila rotary carbide e pili ana i nā kumu he nui, e like me ka wikiwiki, kaomi, ʻoki kuhikuhi, a me nā mea ʻē aʻe. nā kumu i luna.

2. Poor machining surface quality: ʻO ka machining surface quality of cemented carbide rotary files e pili ana i nā kumu he nui, e like me ka paʻakikī o ka waiwai, ka wikiwiki o ka huli ʻana, ka wikiwiki hānai, a me nā mea ʻē aʻe. o na kumu maluna.

Trealamh anailíse agus tástála chun cinn

Tá trealamh anailíse agus tástála chun cinn ag Huijin, mar shampla: anailísí sulfair carbóin, tástálaí TRS, micreascóp meiteagrafach, tástálaí coercivity, tástálaí maighnéadach cóbalt, tástálaí cruas Rockwell, tástálaí cruas Vickers, tástálaí titim, micriméadar, tástálaí roundness, scanóir ultrasonaic, etc. ., is féidir monatóireacht éifeachtach a dhéanamh ar gach próiseas chun ráta cáilithe táirgí a chinntiú.

Cigireacht amhábhar: bain úsáid as anailísí carbóin-sulfair chun a chinneadh go bhfuil comhdhéanamh ceimiceach púdar chomhdhúile tungstain cáilithe.

Tar éis shintéiriú, bain úsáid as an ionstraim chun an t-ábhar a thástáil: tástáil a dhéanamh ar an TRS, microstructure, ábhar cóbalt, cruas an ábhair, slat chomhdhúile cementáilte agus tástáil titim chun a chinntiú nach bhfuil aon locht idirmheánach taobh istigh den ábhar, múnla chomhdhúile cementáilte bán, cuir ultrasonaic. scanóir chun gaineamh Poll taobh istigh den bhán a sheachaint.

Cigireacht ábhair láimhe tar éis shintéiriú: Amharciniúchadh ar lochtanna ábhair ag oibrithe oilte, lena n-áirítear carburization agus dícharbúrú, poill ghaineamh dromchla, scoilteanna beaga.

Seiceáil toisí tar éis shintéiriú: Seiceáil toisí le micriméadar, agus le haghaidh slata chomhdhúile, cuir tástáil cruinn.

Bealaí seachadta / Pacáil

-Comhlachtaí Express: DHL, FedEx, TNT, UPS, etc.

MANAWA PONO: 2023-05-23