- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

F4 F2 Ƙarshen Mill don Ƙarfe Masu Tauri

Ƙarshen Mill don Ƙarfe Mai Tauri (65 HRC)

HJS650 jerin - Ƙarshen Mill don Ƙarƙashin Karfe (65 HRC)

Ya dace da Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin 62-68HRC.

Rufin Babban Ayyukan Duniya na AlCrSiN

F4 F2

Magana ta zahiri:

Ana amfani da ƙarshen niƙa don mutu ana amfani da shi sosai, ana iya shigar da shi kuma a yi amfani da shi a cikin kayan aikin huhu ko lantarki, ingancin samarwa da dorewa fiye da injin niƙa da ƙara yawan lokutan fayil.

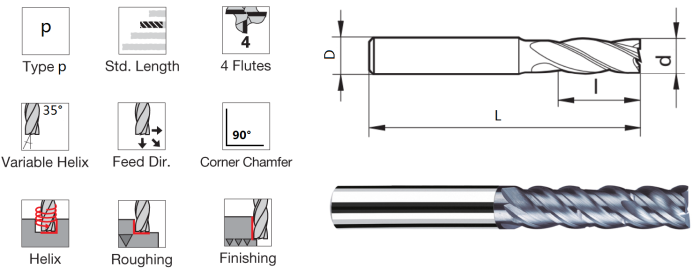

Siffofin:

Ya dace da Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin 62-68HRC.

High ƙarfi, high tauri matrix kayan tushe abu tare da sabon raya shafi, tsawo da kayan aiki rayuwa muhimmanci

An ba da shawarar yin amfani da iska ko sanyaya hazo mai.

Girman yau da kullun:

1.4 Maƙallan Ƙarshen sarewa

Lambar oda Lambar oda | Diamita na Waje | Tsawon sarewa | Gabaɗaya Tsawon | Diamita na Shank |

| (d) ba | (l) ba | (L) ba | (D) ba | |

| HJMJ650-4F-D010-L050 | 1.0 | 3.0 | 50 | 4 |

| HJMJ650-4F-D015-L050 | 1.5 | 4.5 | 50 | 4 |

| HJMJ650-4F-D020-L050 | 2.0 | 6.0 | 50 | 4 |

| HJMJ650-4F-D025-L050 | 2.5 | 7.0 | 50 | 4 |

| HJMJ650-4F-D030-L050 | 3.0 | 8.0 | 50 | 4 |

| HJMJ650-4F-D035-L050 | 3.5 | 10.0 | 50 | 4 |

| HJMJ650-4F-D040-L050 | 4.0 | 11.0 | 50 | 4 |

| HJMJ650-4F-D050-L050 | 5.0 | 13.0 | 50 | 6 |

| HJMJ650-4F-D060-L050 | 6.0 | 16.0 | 50 | 6 |

| HJMJ650-4F-D070-L060 | 7.0 | 17.0 | 60 | 8 |

| HJMJ650-4F-D080-L060 | 8.0 | 20.0 | 60 | 8 |

| HJMJ650-4F-D090-L075 | 9.0 | 25.0 | 75 | 10 |

| HJMJ650-4F-D100-L075 | 10.0 | 25.0 | 75 | 10 |

| HJMJ650-4F-D110-L075 | 11.0 | 28.0 | 75 | 12 |

| HJMJ650-4F-D120-L075 | 12.0 | 30.0 | 75 | 12 |

| HJMJ650-4F-D140-L080 | 14.0 | 35.0 | 80 | 14 |

| HJMJ650-4F-D160-L100 | 16.0 | 45.0 | 100 | 16 |

| HJMJ650-4F-D180-L100 | 18.0 | 48.0 | 100 | 18 |

| HJMJ650-4F-D200-L100 | 20.0 | 50.0 | 100 | 20 |

2. 2 Giwa Kusurwar Radius End mills

| Diamita na Waje | R | Tsawon sarewa | Gabaɗaya Tsawon | Diamita na Shank | |

| (d) ba | (l) ba | (L) ba | (D) ba | ||

| HJMJ650-2F-010-02 | 1 | 0.2 | 2 | 50 | 4 |

| HJMJ650-2F-015-02 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ650-2F-015-03 | 1.5 | 0.2 | 3 | 50 | 4 |

| HJMJ650-2F-020-02 | 2 | 0.2 | 4 | 50 | 4 |

| HJMJ650-2F-020-05 | 2 | 0.5 | 4 | 50 | 4 |

| HJMJ650-2F-025-02 | 2.5 | 0.2 | 5 | 50 | 4 |

| HJMJ650-2F-025-05 | 2.5 | 0.5 | 5 | 50 | 4 |

| HJMJ650-2F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ650-2F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ650-2F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ650-2F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ650-2F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ650-2F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ650-2F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ650-2F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ650-2F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ650-2F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ650-2F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ650-2F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ650-2F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ650-2F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ650-2F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ650-2F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ650-2F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ650-2F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ650-2F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ650-2F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ650-2F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ650-2F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ650-2F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ650-2F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ650-2F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ650-2F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ650-2F-120-20 | 12 | 20 | 24 | 75 | 12 |

| HJMJ650-2F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ650-2F-120-30 | 12 | 3 | 24 | 75 | 12 |

3.4 Flut Corner Radius End Mills

| Diamita na Waje | R | Tsawon sarewa | Gabaɗaya Tsawon | Diamita na Shank | |

| (d) ba | (l) ba | (L) ba | (D) ba | ||

| HJMJ650-4F-030-02 | 3 | 0.2 | 6 | 50 | 4 |

| HJMJ650-4F-030-05 | 3 | 0.5 | 6 | 50 | 4 |

| HJMJ650-4F-030-10 | 3 | 1 | 6 | 50 | 4 |

| HJMJ650-4F-040-02 | 4 | 0.2 | 8 | 50 | 4 |

| HJMJ650-4F-040-05 | 4 | 0.5 | 8 | 50 | 4 |

| HJMJ650-4F-040-10 | 4 | 1 | 8 | 50 | 4 |

| HJMJ650-4F-050-05 | 5 | 0.5 | 10 | 50 | 6 |

| HJMJ650-4F-050-10 | 5 | 1 | 10 | 50 | 6 |

| HJMJ650-4F-060-02 | 6 | 0.2 | 12 | 50 | 6 |

| HJMJ650-4F-060-05 | 6 | 0.5 | 12 | 50 | 6 |

| HJMJ650-4F-060-10 | 6 | 1 | 12 | 50 | 6 |

| HJMJ650-4F-060-15 | 6 | 1.5 | 12 | 50 | 6 |

| HJMJ650-4F-060-20 | 6 | 2 | 12 | 50 | 8 |

| HJMJ650-4F-080-05 | 8 | 0.5 | 16 | 60 | 8 |

| HJMJ650-4F-080-10 | 8 | 1 | 16 | 60 | 8 |

| HJMJ650-4F-080-15 | 8 | 1.5 | 16 | 60 | 8 |

| HJMJ650-4F-080-20 | 8 | 2 | 16 | 60 | 8 |

| HJMJ650-4F-100-05 | 10 | 0.5 | 20 | 75 | 10 |

| HJMJ650-4F-100-10 | 10 | 1 | 20 | 75 | 10 |

| HJMJ650-4F-100-15 | 10 | 1.5 | 20 | 75 | 10 |

| HJMJ650-4F-100-20 | 10 | 2 | 20 | 75 | 10 |

| HJMJ650-4F-100-25 | 10 | 2.5 | 20 | 75 | 10 |

| HJMJ650-4F-100-30 | 10 | 3 | 20 | 75 | 10 |

| HJMJ650-4F-120-05 | 12 | 0.5 | 24 | 75 | 12 |

| HJMJ650-4F-120-10 | 12 | 1 | 24 | 75 | 12 |

| HJMJ650-4F-120-15 | 12 | 1.5 | 24 | 75 | 12 |

| HJMJ650-4F-120-20 | 12 | 2 | 24 | 75 | 12 |

| HJMJ650-4F-120-25 | 12 | 2.5 | 24 | 75 | 12 |

| HJMJ650-4F-120-30 | 12 | 3 | 24 | 75 | 12 |

Abubuwan kayan aiki:

1.Kayan Jiki:

A) Taurin sama ko daidai da 94 HRA;

B) Yawan girma fiye ko daidai da 14.6g/cm³;

C) TRS mafi girma ko daidai da 4100 N/mm²;

D) Yanci na yanayin lokaci na ETA;

E) Babu gurɓatar da wasu kayan;

F) Porosity = A00/ B00 / C00 ;

G) Madaidaicin girman hatsi. Babu girman hatsi da zai iya girma fiye da ƙayyadaddun.

H) Mai hana haɓakar hatsi na Chromium carbide kawai.

2.Duk kayan aikin samarwa, ana amfani da sutura a Jamus, Switzerland, kayan sarrafa kayan aiki;

3.An ba da shawarar yanke ƙasa da 65HRC;

Rufe:

Rufin Babban Ayyukan Duniya na AlCrSiN

Halaye da Aiki

1, Productivity karuwa saboda muhimmanci mafi girma sabon gudun da kuma abinci ga aikace-aikace a cikin wani m kewayon kayan.Muhimmanci inganta yawan aiki.

2, Musamman zane na tsarin kawo kyau daidaito tsakanin tauri, thermo-shock kwanciyar hankali da saura danniya.

Sigar aiki:

| HJMJ650 End mill for die Operation parameter: | |||||||||||||

| HJMJ650-S2 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||||

| Maki | Siffar kayan aiki | Kayan aiki Material | Yanke Zurfin | VC | Kayan aiki Diamita | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| S2 | (mm) | m/min | (mm) | ||||||||||

| HJMJ650 | Square, kusurwa radius | Ƙarfe ƙarfe HRC65 | ap≤1D | 120 | Gudu | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 | 2390 | 1910 |

| (min-1) | |||||||||||||

| ae≤0.05D | Gudun ciyarwa | 380 | 380 | 380 | 380 | 370 | 360 | 310 | 290 | ||||

| (mm/min) | |||||||||||||

| HJMJ650End mill for die Operation parameter: | |||||||||||

| HJMJ650-S4 For Alloy Steel,Hardened Steel-Side Milling | |||||||||||

| Maki | Siffar kayan aiki | Kayan aiki Material | Yanke zurfin (mm) | VC | Kayan aiki Diamita | 2 | 4 | 6 | 8 | 10 | 12 |

| S4 | m/min | (mm) | |||||||||

| HJMJ650 | Square, kusurwa radius | HRC58-62 | ap≤1D | 120 | Gudu | 19100 | 9550 | 6730 | 4780 | 3820 | 3190 |

| (min-1) | |||||||||||

| ae≤0.05D | Gudun ciyarwa | 760 | 760 | 760 | 760 | 730 | 710 | ||||

| (mm/min) | |||||||||||

| HRC68 | ap≤0.7D | 90 | Gudu | 15920 | 11940 | 7960 | 5970 | 4780 | 3980 | ||

| (min-1) | |||||||||||

| ae≤0.03D | Gudun ciyarwa | 510 | 720 | 730 | 720 | 730 | 670 | ||||

| (mm/min) | |||||||||||

Hankali:

Tabbatar cewa yanki na aiki da injin sun tsayayyu kuma yi amfani da madaidaicin mariƙin.

Da fatan za a daidaita saurin, ciyarwa da zurfin yankan bisa ga ainihin yanayin yanke.

Yanayin niƙa don injin niƙa ne na ƙarshe inda tsayin tsayin kayan aikin bai wuce 4*D (mill dia). Lokacin da tsayin tsayin kayan aiki ya fi tsayi, da fatan za a daidaita saurin, ciyarwa da zurfin yankan.

Kamfanin yana da cikakken ruwa masana'antu tsari kayan aiki samar line daga foda albarkatun kasa shiri, mold yin, latsawa, sintering matsa lamba, nika, shafi da shafi post-jiyya. Yana mayar da hankali kan bincike da ƙirƙira na tushe abu, tsagi tsarin, madaidaicin kafa da surface shafi na carbide NC abun da ake sakawa, da kuma kullum inganta machining yadda ya dace, sabis rayuwa da sauran sabon Properties na carbide NC abun da ake sakawa. Bayan fiye da shekaru goma na binciken kimiyya da ƙididdiga, kamfanin ya ƙware da dama na fasaha mai zaman kansa, yana da R & D masu zaman kansu da damar ƙira, kuma yana iya samar da kayan aiki na musamman ga kowane abokin ciniki.