Kayan hatimi na gama gari

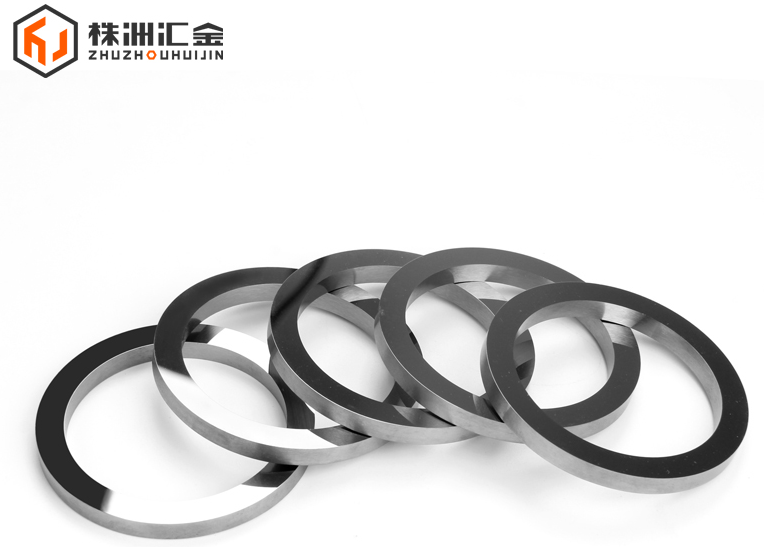

Silicon carbide(碳化硅)

Ana yin siliki carbide ta hanyar haɗa silica da coke. Yana da kamanni da yumbu a cikin sinadarai, amma yana da kyawawan halaye na lubrication kuma yana da wahala, yana mai da shi kyakkyawan maganin sawa mai wahala ga mahalli masu tsauri.

Hakanan za'a iya sake murɗa shi kuma a goge shi ta yadda za'a iya sabunta hatimi sau da yawa tsawon rayuwarsa. Gabaɗaya ana amfani da shi fiye da injiniyanci, kamar a cikin hatimin injina don kyakkyawan juriya na lalata sinadarai, ƙarfin ƙarfi, ƙarfin ƙarfi, juriya mai kyau, ƙaramin juzu'i da juriya mai zafi.

Lokacin amfani dashi don fuskokin hatimin inji, silicon carbide yana haifar da ingantacciyar aiki, haɓaka rayuwar hatimi, ƙarancin kulawa, da ƙarancin tsadar gudu don kayan aiki mai juyawa kamar injin turbines, compressors, da famfo centrifugal. Silicon carbide na iya samun kaddarori daban-daban dangane da yadda aka kera shi. Reaction bonded silicon carbide an kafa shi ta hanyar haɗa barbashi na silicon carbide ga juna a cikin tsarin dauki.

Wannan tsari ba ya tasiri sosai ga yawancin kayan jiki da na zafi na kayan, duk da haka yana iyakance juriyar sinadarai na kayan. Mafi yawan sinadarai na yau da kullun waɗanda ke da matsala sune caustics (da sauran sinadarai masu girma pH) da kuma acid mai ƙarfi, don haka bai kamata a yi amfani da silicon carbide mai ɗaukar hoto tare da waɗannan aikace-aikacen ba.

Silicone carbide mai kaifin baki ana yin shi ta hanyar rarrabuwar barbashi na siliki carbide kai tsaye tare ta amfani da kayan agajin da ba oxide ba a cikin yanayi mara kyau a yanayin zafi sama da 2,000°C. Saboda rashin kayan abu na biyu (kamar silicon), kayan da aka haɗa kai tsaye yana da juriya ta hanyar sinadarai zuwa kusan kowane ruwa da yanayin tsari da wataƙila za a iya gani a cikin famfo na centrifugal.

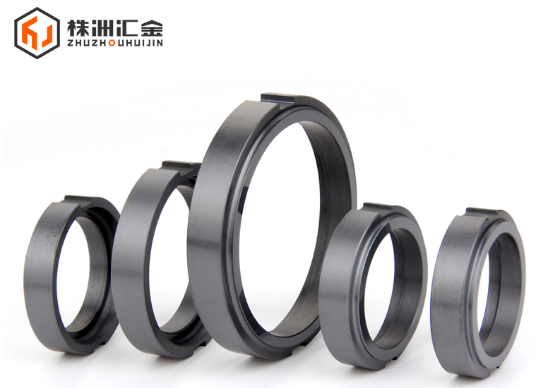

Tungsten carbide(硬质合金)

Tungsten carbide abu ne mai iya jujjuyawar abubuwa kamar silicon carbide, amma ya fi dacewa da aikace-aikacen matsa lamba saboda yana da ƙarfi mafi girma wanda ke ba shi damar jujjuya ɗanɗano kaɗan kuma yana hana murdiya fuska. Kamar siliki carbide, ana iya sake latsa shi kuma a goge shi.

Tungsten carbide galibi ana kera su azaman simintin carbide don haka babu wani yunƙuri na haɗa tungsten carbide da kanta. Ana ƙara ƙarfe na biyu don ɗaure ko simintin barbashi na tungsten carbide tare, yana haifar da wani abu wanda ke da abubuwan haɗin gwiwar duka biyun carbide na tungsten da mai ɗaure ƙarfe.

An yi amfani da wannan don fa'ida ta hanyar samar da ƙarfi mai ƙarfi da ƙarfin tasiri fiye da yadda zai yiwu tare da tungsten carbide kaɗai. Daya daga cikin raunin simintin tungsten carbide shine babban yawansa. A baya, an yi amfani da tungsten carbide mai ɗaure cobalt, duk da haka a hankali an maye gurbinsa da tungsten carbide mai ɗaure nickel saboda rashin kewayon daidaitawar sinadarai da ake buƙata don masana'antu.

Tungsten carbide mai ɗaure nickel ana amfani dashi ko'ina don hatimi fuskoki inda ake son babban ƙarfi da ƙaƙƙarfan kaddarorin, kuma yana da kyakkyawar dacewa da sinadarai gabaɗaya iyakance ta nickel kyauta.

yumbu(陶瓷))

yumbu kayan da ba na ƙarfe ba ne da aka yi daga mahallin halitta ko na roba, galibi alumina oxide ko alumina. Yana da babban wurin narkewa, babban tauri, babban juriya da juriya da iskar oxygen, don haka ana amfani dashi sosai a masana'antu kamar injina, sinadarai, man fetur, magunguna da motoci.

Hakanan yana da kyawawan kaddarorin dielectric kuma galibi ana amfani dashi don insulators na lantarki, sa kayan gyara masu juriya, kafofin watsa labarai, da kayan aikin zafin jiki. A cikin manyan tsarkakakku, alumina yana da kyakkyawan juriya na sinadarai ga mafi yawan ruwaye na tsari ban da wasu ƙaƙƙarfan acid, yana haifar da amfani da shi a aikace-aikacen hatimin injina da yawa. Koyaya, alumina na iya karyewa cikin sauƙi a ƙarƙashin girgizar zafi, wanda ya hana amfani da shi a wasu aikace-aikacen da wannan na iya zama matsala.

Carbon(碳)

Carbon da ake amfani da shi a cikin hatimin fuska shine mixture na amorphous carbon da graphite, tare da kaso na kowane ƙayyadaddun kaddarorin jiki a kan matakin karshe na carbon. Wani abu ne marar aiki, tsayayye wanda zai iya zama mai mai da kansa.

Ana amfani dashi ko'ina azaman ɗayan fuskokin ƙarshen biyu a cikin hatimin injina, kuma shima sanannen abu ne don keɓaɓɓen hatimin dawakai da zoben fistan a ƙarƙashin busassun ko ƙarami na lubrication. Wannan cakuda carbon/graphite kuma za'a iya yin ciki da wasu kayan don ba shi halaye daban-daban kamar rage girman kai, ingantaccen lalacewa ko ingantaccen ƙarfi.

Hatimin hatimin carbon ɗin da aka haɗa da thermoset shine ya fi kowa don hatimin injina, tare da mafi yawan resin da ke cikin carbons masu iya aiki a cikin kewayon sinadarai daga tushe mai ƙarfi zuwa ƙarfi acid. Hakanan suna da kyawawan kaddarorin juzu'i da isassun modules don taimakawa sarrafa murdiya. Wannan kayan ya dace da aikin gama-gari zuwa 260°C (500°F) a cikin ruwa, masu sanyaya, mai, mai, hanyoyin sinadarai masu haske, da aikace-aikacen abinci da magunguna.

Hakanan an tabbatar da cewa an tabbatar da nasarar hatimin carbon na Antimony saboda ƙarfi da yanayin antimony, yana mai da kyau ga aikace-aikacen matsa lamba lokacin da ake buƙatar abu mai ƙarfi da ƙarfi. Waɗannan hatimin su ma sun fi juriya ga ƙyanƙyashe a aikace-aikace tare da maɗaukakiyar ruwa mai ɗanko ko haske mai ƙarfi, yana mai da shi madaidaicin maki don aikace-aikacen matatar da yawa.

Hakanan za'a iya shigar da carbon da tsoffin fina-finai kamar fluorides don bushewar gudu, cryogenics da aikace-aikacen vacuum, ko masu hana oxidation kamar phosphates don babban zafin jiki, saurin gudu, da aikace-aikacen injin turbine zuwa 800ft/ sec da kusa da 537°C (1,000°F).

Buna(丁钠橡胶))

Buna (wanda kuma aka sani da nitrile roba) elastomer mai tsada mai tsada don O-rings, sealants da samfuran gyare-gyare. An san shi sosai don aikin injiniya kuma yana aiki sosai a cikin tushen mai, petrochemical da aikace-aikacen sinadarai. Hakanan ana amfani da shi sosai don ɗanyen mai, ruwa, barasa daban-daban, man shafawa na silicone da aikace-aikacen ruwa mai ruwa saboda rashin sassauci.

Kamar yadda Buna shine copolymer na roba na roba, yana aiki da kyau a aikace-aikacen da ke buƙatar mannewa da ƙarfe da abu mai jurewa, kuma wannan yanayin sinadari kuma yana sa ya dace don aikace-aikacen rufewa. Bugu da ƙari kuma, zai iya jure ƙananan yanayin zafi kamar yadda aka tsara shi tare da ƙarancin acid da juriya na alkali.

Buna yana iyakance a aikace-aikace tare da matsanancin yanayi kamar yanayin zafi, yanayi, hasken rana da aikace-aikacen juriya na tururi, kuma bai dace da ma'auni mai tsafta (CIP) mai tsabta da ke ɗauke da acid da peroxides ba.

EPDM三元乙丙橡胶)

EPDM roba ce ta roba da aka fi amfani da ita a cikin kera, gini da aikace-aikacen injina don hatimi da O-ring, tubing da washers. Yana da tsada fiye da Buna, amma yana iya jure nau'ikan yanayin zafi, yanayi da kaddarorin inji saboda tsayin daka mai tsayi. Yana da m kuma manufa domin aikace-aikace shafe ruwa, chlorine, bleach da sauran alkaline kayan.

Saboda kaddarorin sa na roba da mannewa, da zarar an miƙe shi, EPDM ya dawo zuwa ga ainihin siffarsa ba tare da la'akari da yanayin zafi ba. Ba a ba da shawarar EPDM don man fetur, ruwaye, chlorinated hydrocarbon ko aikace-aikacen kaushi na hydrocarbon.

Viton(氟橡胶))

Viton abu ne mai dorewa, babban aiki, mai kyalli, samfurin roba na hydrocarbon da aka fi amfani dashi a cikin O-Rings da hatimi. Ya fi sauran kayan roba tsada amma shine zaɓin da aka fi so don mafi ƙalubale da buƙatun rufewa.

Mai jure wa ozone, iskar oxygen da matsanancin yanayin yanayi, gami da kayan kamar aliphatic da hydrocarbons aromatic, ruwa mai halogenated da kayan acid mai ƙarfi, yana ɗaya daga cikin mafi ƙarfin fluoroelastomer.

Zaɓin madaidaicin abu don hatimiing yana da mahimmanci don nasarar aikace-aikacen. Duk da yake yawancin kayan hatimi suna kama da juna, kowannensu yana yin amfani da dalilai iri-iri don saduwa da kowane takamaiman buƙatu.

Farashin GFPTFE

GFPTFE yana da kyakkyawan juriya na sinadarai, kuma gilashin da aka ƙara yana rage juzu'i na fuskokin rufewa. Yana da manufa don ingantaccen aikace-aikace masu tsabta kuma yana da arha fiye da sauran kayan. Akwai ƙananan bambance-bambancen da ke akwai don mafi dacewa da hatimin zuwa buƙatu da muhalli, haɓaka aikin sa gaba ɗaya.

BAYAN LOKACI: 2023-12-08