- English

- Español

- Português

- Deutsch

- Français

- Italiano

- हिन्दी

- Русский

- 한국어

- 日本語

- العربية

- ภาษาไทย

- Türkçe

- Nederlands

- Tiếng Việt

- Bahasa Indonesia

- עברית

- Afrikaans

- አማርኛ

- Azerbaijani

- беларуская мова

- Български

- বাংলা

- bosanski jezik

- Català

- Binisaya

- Corsu

- Čeština

- Cymraeg

- Dansk

- Ελληνικά

- Esperanto

- Eesti Keel

- Euskara

- فارسی

- Suomi

- Frysk

- Gaeilge

- Gàidhlig

- Galego

- ગુજરાતી

- Harshen Hausa

- ʻŌlelo Hawaiʻi

- Hmoob

- Hrvatski

- Kreyòl Ayisyen

- Magyar

- Հայերեն

- Asụsụ Igbo

- Íslenska

- Basa Jawa

- ქართული

- Қазақ тілі

- ភាសាខ្មែរ

- ಕನ್ನಡ

- Kurdî

- кыргыз тили

- Lëtzebuergesch

- ພາສາລາວ

- Lietuvių

- Latviešu

- Malagasy fiteny

- Te Reo Māori

- македонски

- മലയാളം

- Монгол

- मराठी

- Bahasa Melayu

- Malti

- မြန်မာစာ

- नेपाली

- Norsk

- Chinyanja

- ଓଡ଼ିଆ oṛiā

- ਪੰਜਾਬੀ

- Polski

- پښتو

- Română

- Ikinyarwanda

- سنڌي

- සිංහල

- Slovenčina

- slovenščina

- Gagana Sāmoa

- ChiShona

- Af-Soomaali

- Shqip

- Српски

- Sesotho

- Basa Sunda

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- Тоҷикӣ

- Türkmençe

- Filipino

- татарча

- ئۇيغۇر تىلى

- Українська

- اردو

- Oʻzbek tili

- isiXhosa

- ײִדיש

- èdè Yorùbá

- 中文(简体)

- 中文(漢字)

- isiZulu

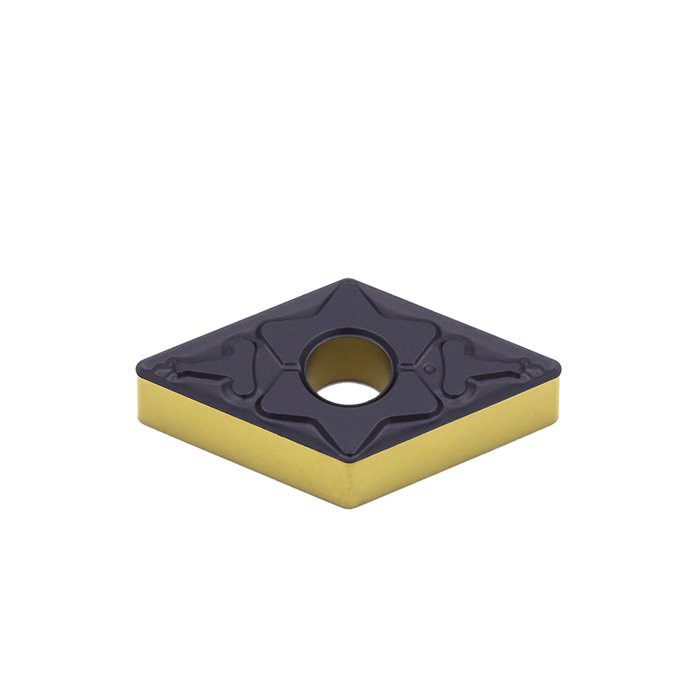

DNMG ynfoegje

DNMG ynfoegje

Produktnamme: DNMG Inserts

Searjes: DNMG

Chip-Breakers: AM / AR / AS / BF / BM / BR / CM / DM / SM / TM

Produkt Ynformaasje:

Turing ynfoegje DNMG. Double-Sided 55 ° Rhombic Inserts. klaringshoek 0°. Optimalisearre substraat- en coatingkombinaasje foar topprestaasjes. Geometry fan insert optimalisearre foar ferwurkjen applikaasje. Grade en mjitkunde jouwe proses betrouberens. Excellent wear detection soarget derfoar dat alle rânen wurde used.With in ferskaat oan ferskillende maten beskikber, wy meitsje it maklik te selektearjen de ideale turning ynfoegje foar jo plande applikaasjes.

Spesifikaasjes:

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | Klasse | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK4235 | JK4335 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | ||||

P Semi Finishing | DNMG150404-AM | 0.60-5.40 | 0.10-0.30 | • | O | • | O | O | |||||||

DNMG150408-AM | 1.20-5.40 | 0.20-0.60 | • | O | • | O | O | ||||||||

DNMG150412-AM | 1.80-5.40 | 0.30-0.90 | • | O | • | O | O | ||||||||

DNMG150604-AM | 0.60-5.40 | 0.10-0.30 | • | O | • | O | O | ||||||||

DNMG150608-AM | 1.20-5.40 | 0.20-0.60 | • | O | • | O | O | ||||||||

DNMG150612-AM | 1.80-5.40 | 0.30-0.90 | • | O | • | O | O | ||||||||

• : Recommended Grade

O: Opsjonele Grade

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | Klasse | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK4235 | JK4335 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | ||||

P Rough Machining | DNMG150408-AR | 0.80-4.0 | 0.15-0.50 | • | O | ||||||||||

DNMG150412-AR | 1.20-4.0 | 0.15-0.65 | • | O | |||||||||||

DNMG150608-AR | 0.80-4.0 | 0.15-0.50 | • | O | |||||||||||

DNMG150612-AR | 1.20-4.0 | 0.15-0.65 | • | O | |||||||||||

• : Recommended Grade

O: Opsjonele Grade

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | Klasse | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | JR1525 | JR1330 | ||||

M Finishing | DNMG150404-BF | 0.25-2.90 | 0.05-0.15 | • | • | O | O | ||||||||

DNMG150408-BF | 0.50-2.90 | 0.10-0.30 | • | • | O | O | |||||||||

DNMG150412-BF | 0.75-2.90 | 0.15-0.45 | • | • | O | O | |||||||||

DNMG150604-BF | 0.25-2.90 | 0.05-0.15 | • | • | O | O | |||||||||

DNMG150608-BF | 0.50-2.90 | 0.10-0.30 | • | • | O | O | |||||||||

DNMG150612-BF | 0.75-2.90 | 0.15-0.45 | • | • | O | O | |||||||||

• : Recommended Grade

O: Opsjonele Grade

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | Klasse | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | JR1525 | JR1330 | ||||

M Semi Finishing | DNMG150404-BM | 0.30-3.90 | 0.08-0.25 | O | O | • | O | O | |||||||

DNMG150408-BM | 0.65-3.90 | 0.15-0.45 | O | O | • | O | O | ||||||||

DNMG150412-BM | 0.95-3.90 | 0.25-0.65 | O | O | • | O | O | ||||||||

DNMG150604-BM | 0.30-3.90 | 0.08-0.20 | O | O | • | O | O | ||||||||

DNMG150608-BM | 0.65-3.90 | 0.15-0.45 | O | O | • | O | O | ||||||||

DNMG150612-BM | 0.95-3.90 | 0.25-0.65 | O | O | • | O | O | ||||||||

• : Recommended Grade

O: Opsjonele Grade

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | Klasse | |||||||||||

| CVD | PVD | ||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1325 | JR1528 | JR1330 | ||||

M Rough Machining | DNMG150404-BR | 0.30-3.90 | 0.08-0.25 | O | O | O | • | • | O | ||||||

DNMG150408-BR | 0.65-3.90 | 0.15-0.45 | O | O | O | • | • | O | |||||||

DNMG150412-BR | 0.95-3.90 | 0.25-0.65 | O | O | O | • | • | O | |||||||

DNMG150604-BR | 0.30-3.90 | 0.08-0.20 | O | O | O | • | • | O | |||||||

DNMG150608-BR | 0.65-3.90 | 0.15-0.45 | O | O | O | • | • | O | |||||||

DNMG150612-BR | 0.95-3.90 | 0.25-0.65 | O | O | O | • | • | O | |||||||

• : Recommended Grade

O: Opsjonele Grade

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | CVD | |||

JK3020 | JK3040 | JK3315 | JK3415 | ||||

K Semi Finishing | DNMG150404-CM | 0.40-3.90 | 0.08-0.25 | • | O | ||

DNMG150408-CM | 0.80-3.90 | 0.15-0.45 | • | O | |||

DNMG150412-CM | 1.20-3.90 | 0.25-0.65 | • | O | |||

DNMG150604-CM | 0.40-3.90 | 0.08-0.20 | • | O | |||

DNMG150608-CM | 0.80-3.90 | 0.15-0.45 | • | O | |||

DNMG150612-CM | 1.20-3.90 | 0.25-0.65 | • | O | |||

• : Recommended Grade

O: Opsjonele Grade

| Oanfraach | Type | Ap (mm) | Fn (mm/omw.) | Klasse | ||||||||||||

| CVD | PVD | |||||||||||||||

JK4215 | JK4315 | JK4225 | JK4325 | JK1025 | JK1325 | JK1525 | JK1328 | JR1010 | JR1520 | JR1525 | JR1028 | JR1030 | ||||

S Semi Finishing | DNMG150404-DM | 0.40-3.90 | 0.08-0.25 | O | O | O | • | • | O | O | ||||||

DNMG150408-DM | 0.80-3.90 | 0.15-0.45 | O | O | O | • | • | O | O | |||||||

DNMG150412-DM | 1.20-3.90 | 0.25-0.65 | O | O | O | • | • | O | O | |||||||

DNMG150604-DM | 0.40-3.90 | 0.08-0.20 | O | O | O | • | • | O | O | |||||||

DNMG150608-DM | 0.80-3.90 | 0.15-0.45 | O | O | O | • | • | O | O | |||||||

DNMG150612-DM | 1.20-3.90 | 0.25-0.65 | O | O | O | • | • | O | O | |||||||

• : Recommended Grade

O: Opsjonele Grade

Oanfraach:

DNMG cutting ark brûkt foar grooving, profilearjen, finishing, en oare Machtigingsformulier applikaasjes.

Earste kar foar eksterne draaien fan slanke wurkstikken fan alle soarten stiel, geskikt foar medium finish en finish.

It bedriuw hat in folsleine produksjeline foar blêdproduksjeprosesapparatuer fan tarieding fan poedergrûnstoffen, skimmel meitsjen, drukken, druk sinterjen, slypjen, coating en neibehanneling fan coating. It rjochtet him op it ûndersyk en ynnovaasje fan de basis materiaal, groove struktuer, precision foarmjen en oerflak coating fan carbid NC Inserts, en hieltyd ferbetteret de Machtigingsformulier effisjinsje, libbensdoer en oare cutting eigenskippen fan carbid NC Inserts. Nei mear as tsien jier fan wittenskiplik ûndersyk en ynnovaasje, it bedriuw hat behearske in oantal ûnôfhinklike kearn technologyen, hat ûnôfhinklike R & D en design mooglikheden, en kin foarsjen maatwurk produksje foar elke klant.